Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIndependent Ohio phone company modernizes monitoring system

| Field | Details |

|---|---|

| Industry | Independent Telephone Company |

| Company Type | Regional Telecom Provider |

| Geography/Coverage | Urbana, Ohio (Columbus-Dayton) |

| Primary Challenge | Outdated monitoring after softswitch upgrade |

| Solution Deployed | T/Mon SLIM with NetGuardian RTU fleet |

| Key Result | Successful deployment with full visibility |

| Products Used | T/Mon SLIM, NetGuardian RTUs |

CT Communications is an independent telephone company located in Urbana, Ohio, between Columbus and Dayton. As an independent provider, CT stays ahead of the competition by bringing clients the latest innovations and superior service.

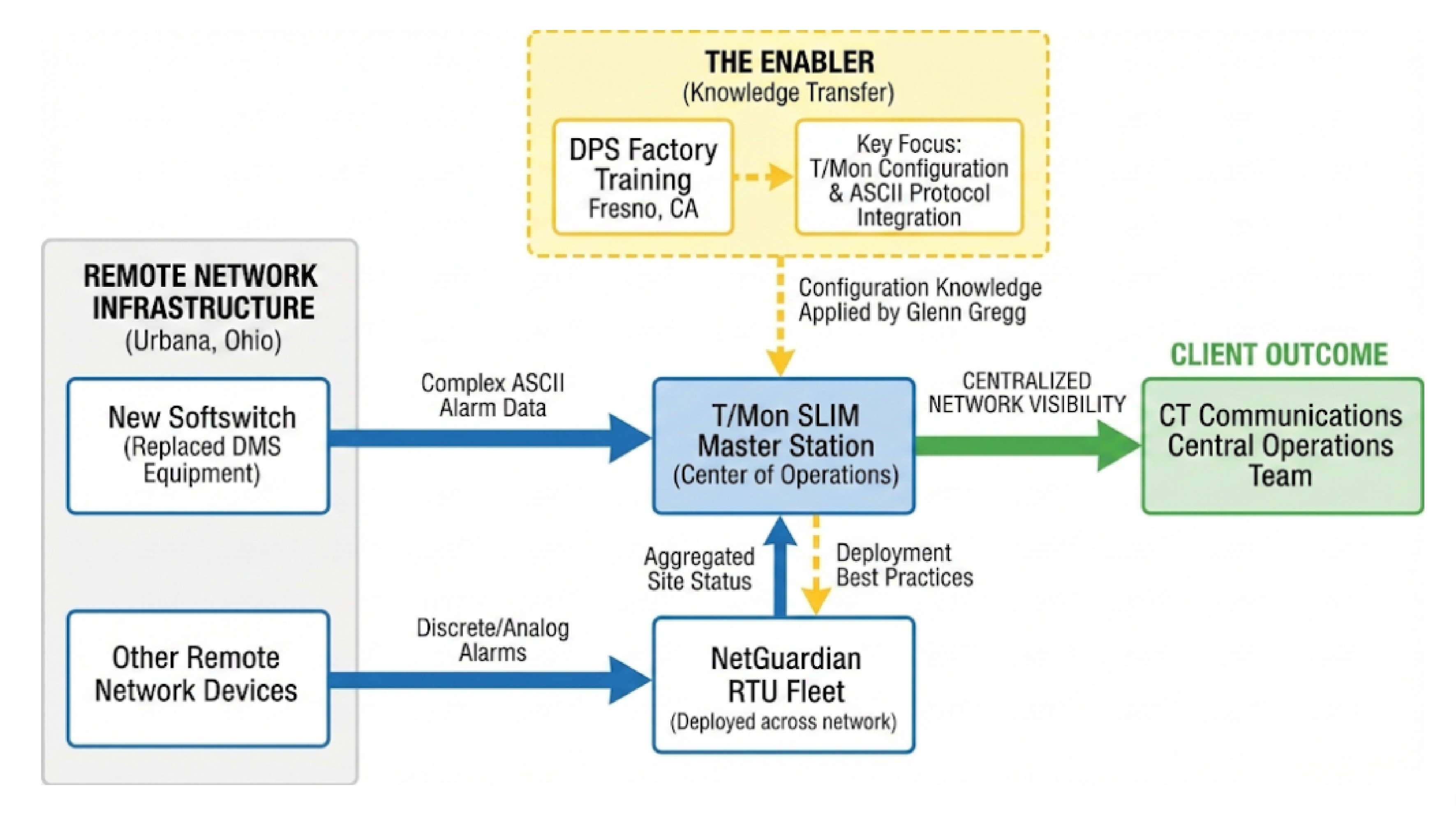

After retiring their DMS equipment and replacing it with a softswitch, CT Communications faced a monitoring gap. Their existing system couldn't provide visibility into the new infrastructure. Glenn Gregg, a Central Office Technician, needed an advanced remote monitoring system to collect alarms from the softswitch and other network devices.

Gregg worked with DPS sales to find a solution. The goal was to provide visibility where existing equipment could not. After evaluating their options, CT deployed a T/Mon SLIM master at their center of operations, along with NetGuardian RTUs across their network.

Prior to deployment, Gregg traveled to DPS headquarters in Fresno, California to attend Factory Training. The hands-on training prepared him to configure and manage the T/Mon SLIM system effectively.

| Phase | Description |

|---|---|

| Pre-Deployment Training | Gregg attended Factory Training to learn T/Mon SLIM configuration and best practices for their specific monitoring needs. |

| Hands-On Learning | Training included dedicated time on ASCII protocol integration, which proved essential for CT's monitoring requirements. |

| Implementation | Knowledge from training, combined with DPS tech support and site preparation worksheets, enabled smooth deployment. |

| Team Expansion | CT plans to send additional employees to Factory Training based on the positive experience. |

The new T/Mon system provided complete network visibility. The combination of training and equipment resulted in successful deployment. "The class was super," Gregg said. "It was very informative and left nothing untouched."

| Outcome | Impact |

|---|---|

| Training Value | Education covering all system operation aspects |

| Personal Service | Welcoming environment with hands-on attention |

| Protocol Mastery | ASCII training directly applicable to CT's needs |

| Confident Deployment | Gregg installed and configured system independently |

"At all my other training sessions, I've been nothing but a number. I'd never been to an environment that was so welcoming."

Glenn Gregg, Central Office Technician, CT Communications

Talk to an Application Engineer | 1-800-693-0351

| Comprehensive Training | Multi-day training covered all system aspects thoroughly. |

|---|---|

| Practical Application | ASCII protocol training supported CT's monitoring requirements. |

| Personal Attention | DPS provided welcoming, hands-on instruction throughout. |

| Successful Implementation | Technician deployed system confidently with minimal support. |

Network alarm master providing centralized monitoring.

Remote units monitoring equipment and environmental conditions.

Why is hands-on training important for monitoring deployments?

Training ensures your team understands system configuration, protocol integration, and best practices before deployment. This reduces implementation time. It helps you maximize your monitoring investment. At DPS, Factory Training includes hands-on experience with actual equipment, not just theory.

How does Factory Training differ from other training programs?

DPS Factory Training is conducted at our Fresno headquarters with small class sizes. You get direct access to engineering staff. You'll work with the actual equipment you're deploying. You'll tour our manufacturing facility. You receive personalized attention for your specific monitoring challenges.

What protocols are most important for telecommunications monitoring?

Common protocols for telecom monitoring include SNMP for network equipment. ASCII handles text-based alarm messages from various devices. TL1 works with traditional telecom equipment. The specific protocols you need depend on your equipment mix. DPS systems support 30+ protocols to integrate with virtually any infrastructure.

How long does it take to deploy a monitoring system after training?

With proper training, most customers can deploy their T/Mon and RTU systems within days. The training provides configuration knowledge. DPS tech support and site preparation worksheets guide the physical installation. Many customers handle installation with their existing staff.

Can independent telephone companies afford modern monitoring systems?

Modern monitoring systems prevent expensive outages and reduce truck rolls. They typically pay for themselves quickly. DPS offers flexible deployment options. We work with independent telcos to design systems that fit specific budgets and requirements. The investment in reliability protects revenue-generating infrastructure.

Whether you're upgrading from outdated systems or building new monitoring capabilities, DPS Telecom provides the equipment, training, and support to protect your network infrastructure.

Get a Free Consultation | 1-800-693-0351