Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayPositive Train Control (PTC) has changed the safety landscape of the railroad industry forever. Since its federal mandate in 2008 (and taking much broader effect in 2015), it has gone from a compliance checkbox to a real-time automation system that saves lives and keeps freight and passengers moving across the country.

But here's something you might not hear enough:

PTC can't work unless its monitoring systems do.

If a trackside device fails, if an onboard router loses communication, or if a cabinet overheats without anyone knowing, the consequences (delays, fines, or even safety incidents) can be serious.

As we head into 2026, let's break down how PTC works, why it's so complex to maintain, and how you can build an infrastructure that keeps it online - without scrambling every time there's an issue in the field.

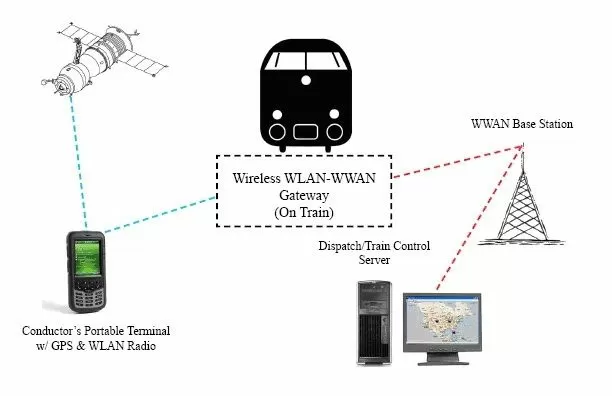

If you've worked in the rail industry for any length of time, you know that today's trains are far more than just metal and fuel. They're networked systems - closely integrated with GPS, AI, broadband communications, and field sensors. All these parts must work together, in real-time, to keep operations safe.

Let's walk through a basic overview of PTC operation:

That's a lot of moving parts:

If any part of that ecosystem fails - whether it's a power loss at a trackside cabinet, a vandalized antenna, or a broken temperature sensor - your entire system can become unreliable fast.

And when we say unreliable, we don't mean "a little annoying." We're talking about:

That's a big price to pay for something as simple as a failed battery or an unmonitored temperature spike. Unfortunately, even rare events happen sometimes. You need to detect them so that you can respond.

Many rail operators still rely on minimal - or even reactive - monitoring at their remote PTC sites.

You might see setups like:

This creates a few big problems down the line:

If your equipment fails and you don't know about it, you can't fix it. And when PTC is down, it means train delays - or worse.

Without smart monitoring, field crews get vague work orders like "Check this site" with no clue what's wrong. That means wasted truck rolls, longer MTTR, and higher labor costs.

PTC systems have to meet strict availability targets. If your documentation is scattered across different systems - or worse, nonexistent - it becomes hard to prove that you met uptime requirements during audits.

Instead of getting early warnings about rising temperatures, increasing latency, or deteriorating voltage, you only get notified after the failure happens.

That's not how a modern, AI-assisted safety system should operate.

Let's imagine something better - something that's already happening for major U.S. railroads.

Imagine a system where:

That's what a good and modern remote monitoring solution delivers.

It's how you eliminate the "last-mile" blind spots that plague so many PTC rollouts. It's how you make sure the system you've invested millions into stays online and compliant.

At DPS Telecom, we've spent more than 30 years helping clients monitor the critical infrastructure that makes their networks - and their businesses - work.

In fact, we've worked with major rail operators across North America to solve the exact problems we're talking about here.

NetGuardian Remote Telemetry Units (RTUs) are installed at trackside cabinets and other remote sites to monitor everything that matters in your PTC network.

These RTUs give you:

Whether you need a compact DIN-rail RTU or a 1RU high-density model, we've got a configuration that will fit your cabinet, your environment, and your budget.

Bonus: These aren't "off the shelf" units from a company that also makes HVAC systems. We design, build, and test these units ourselves, here in the U.S.

When you've got hundreds of sites, you can't afford to manage each one separately. That's where T/Mon becomes a helpful tool.

T/Mon LNX is your central alarm master system. It collects alerts and data from every NetGuardian (and even third-party devices) and brings them into one screen for your operations team.

Key features of this master station include:

Together, NetGuardian and T/Mon create a complete, closed-loop visibility and control system that's purpose-built for large, distributed networks like Positive Train Control.

Let's say you've got a track segment in the Midwest that includes:

You install a NetGuardian RTU inside the cabinet to monitor:

That RTU will report alarms via SNMP over LTE and fiber to your central T/Mon server. If the temperature starts creeping above your threshold - or the battery voltage drops due to cloudy weather - you get an instant alert. That way, you dispatch techs before a shutdown occurs. This prevents delays and guesswork.

Some of the real-world improvements our rail clients see are:

You've invested millions into Positive Train Control - and you've probably seen firsthand how effective it can be.

But you also know that complex systems need smart support to cover the basics of backup power and communications infrastructure.

Let's make sure your PTC network stays online, monitored, and protected.

Call DPS Telecom at 1-800-693-0351

Or email us at sales@dpstele.com

Let's talk about your PTC project and get you the tools to keep it online, safe, and resilient - 365 days a year.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...