Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWindshield time is all the unproductive time that your technicians spend traveling to and from remote sites during a truck roll. You probably know exactly that this gets expensive really fast.

There's no question about it: truck rolls are costly. When you are paying your techs to spend hours of their time sitting in a car, you are greatly raising your costs and wasting their time.

And what if it takes a snowcat or even a helicopter to get to a remote site? Do you have technicians that spend the entire day in their trucks driving from site to site? Is your technician dispatched to a site every time there is a problem just to find out what the issue is?

Here at DPS, we've been helping hundreds of clients to avoid allocating large portions of their budget to truck roll costs and inefficiencies. You probably can't afford to leave your sites unchecked and unmonitored, so we aim to help you find better solutions.

Resolving more issues remotely helps, but not all monitoring systems are created equal. In order to really avoid unnecessary truck rolls, you need to know what the best systems should have.

So, let's dive in.

Reducing truck roll and windshield time involves putting in place a remote site monitoring system. This is a solution for better managing the status of equipment at distant locations, so you don't have to physically be present at your remote sites.

Many different industries deploy remote monitoring, such as railway companies, utility companies, and phone and cellular companies. And, although the technical specifics vary between remote site monitoring systems for each different industry, they all share a common general topology.

Remote telemetry devices, or simply RTUs, are deployed at each remote site to collect system alarms from the equipment stationed there, and also monitor the surrounding environment for critical factors - such as temperature, humidity, physical intrusion, etc.

After all this data has been collected at each remote site, it must be aggregated in order to be presented to a human operator. This job is handled by a central master station.

These master stations necessarily have much more processing power than the average remote device, although they may not have the same level of protection against industrial environments (they are usually deployed in offices rather than remote huts and cabinets).

Master stations commonly feature redundant architecture, and simultaneously running a redundant pair of master stations is an industry best practice for superior remote site monitoring.

With both of these devices types working together, you and your techs are able to accomplish remote site monitoring. You'll have a good situational awareness across perhaps thousands of square miles containing remote sites. If a problem arises at a site, an appropriate response can be issued to ensure that a particular remote site problem won't grow until it becomes a widespread network outage.

You don't have to put up with windshield time and truck roll expenses any longer. Let's take a look at the top 10 most common leading causes of windshield time - and how you can avoid them.

Unscheduled repairs create uncontrollable windshield time costs. If you don't know how many truck rolls are going to happen this month, you won't know what your operational expenses will be.

You can bring your outages and your truck rolls under control with proactive network monitoring. Getting visibility of growing problems before they cause outages lets you take care of them during regularly scheduled maintenance. Check your event logs for unplanned outages and truck rolls. If you're visiting your sites more often than schedules, it's a sign you need better monitoring.

Many problems can be solved by simply turning a switch, such as starting a backup generator, for instance. However, if the switch is 20 miles away, that simple solution becomes pretty expensive.

Every device at your sites can and should be remotely operated through your network monitoring equipment. Remote operation enables you to solve more network problems right from the Network Operations Center (NOC), with no truck roll necessary.

Check the most recent full audit of your remote site equipment and see how much of your equipment isn't controlled from your NOC. After that, compare that list against your event logs. Determine if any of the uncontrolled gear caused a truck roll in the last year. This exercise can help you determine if you need to get additional remote controls in place, within your network.

If you don't know what the problem is, how can you be sure you're prepared to correct it?

Technicians often travel to remote sites to diagnose a problem, and then have to return to the central office to grab the correct tools, the correct supplies, or to call a technician with specialized training.

A quality network alarm monitoring system will give you detailed information about alarm events, ensuring that you'll really know what the problem is and can send the right person with the right tools to do the job. How much detailed information are you getting from your current monitoring system? Are you confident that, if a repair is required, you can always send a fully prepared tech?

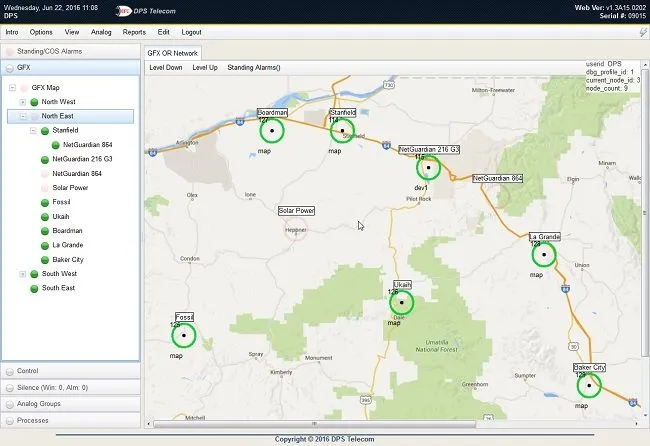

Truck rolls costs can be kept to a minimum if you can pinpoint where problems on your network occur. How often have your technicians had to drive for hours just to locate remote sites and find problems?

You can correct this issue with a network monitoring system that can display a graphic "war-room" representation of your network on a map of your physical locations. Graphic displays can zoom from the national level to region, city, site, rack, device, and alarm point. You'll see exactly where alarms are occurring.

If you don't have a keyless entry system for your remote sites, techs have to come to the central office to obtain remote site keys. If a site needs repairs unexpectedly, technicians may even have to return from the field, just to fetch a key and return to the field again, effectively doubling windshield time.

Installing a keyless entry system not only enhances security but also keeps techs in the field instead of driving back simply to retrieve a key.

How much visibility do you have of your remote-site monitoring equipment? Do you need to have someone on-site to verify connections and polling between your RTUs and the master station?

You have a remote monitoring system to reduce truck rolls, not to create more of it. So, make sure your monitoring equipment supports remote access, this way you can turn up and troubleshoot your units from the NOC.

Site visits are justified if you're physically installing equipment, but not if you're simply sending data. If you have to send a technician to provision a unit, your network can't change and grow without creating more costs of truck rolls and windshield time.

Quality modern network monitoring equipment supports remote provisioning by LAN, so you can manage your database, and make changes whenever necessary, directly from your NOC. This way you or your techs won't have to travel to remote sites - every extra mile is money lost.

If you can't update your equipment without physically visiting the site, you have an uncomfortable choice between keeping your monitoring at its current level or incurring more expensive windshield time.

Check your sites for network monitoring equipment that requires a direct serial connection for a firmware download - or even worse, older legacy equipment whose firmware can't be updated except by swapping a circuit board. Quality modern equipment will support firmware updates by LAN.

Do you have to travel to your remote sites to diagnose and debug communications problems? Do you have to connect special equipment to your transmission lines? If you do, you're creating unnecessary truck rolls.

See if your current monitoring system supports a Protocol Analyzer mode. You can and should be able to debug communications traffic right from your alarm monitoring console.

Are you able to connect to your serial equipment from the NOC? Any data connection that doesn't support LAN is a powerful generator of truck rolls and windshield time.

You can eliminate this problem with LAN-based monitoring equipment that supports reach-through connections to your serial equipment.

Now that you know how an efficient remote monitoring system can help you avoid wasted truck rolls, let's take a look at what you should look for in a competent RTU.

Here are other useful features you should keep in mind when considering a network monitoring system:

Do you have plenty of other work to do outside of remote monitoring? Don't waste time and money on truck rolls when you could simply select smarter equipment from the start. Smart RTUs featuring remote configuration allow you to monitor your site from wherever you are, without dispatching techs for anything less than a major problem.

However, knowing everything you can and should monitor can be challenging.

We have more than 30 years of experience as a custom remote monitoring solutions provider and we know that questions and uncertainties are common in the earliest phases of monitoring systems deployment. So, to help you make an informed decision, our team of experts put together the DPS Remote Site Survey.

This document is a guide that will take you through the process of brainstorming all elements that you want or need to monitor to keep an eye on at your remote sites. Download your free copy of the DPS Remote Site Survey.

However, if you prefer a more detailed and personalized way to plan your remote monitoring system, to ensure a perfect fit, you can also have a consultation with one of our application engineers. Simply contact us and we can help you determine your real needs, both for the present and the future.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.