Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayI work for a full-service manufacturer of remote-monitoring equipment. I've helped thousands of people get a handle on their networks, but I freely admit that "full service" is not always the best option. For every person I've helped, there's another where it just wasn't the right fit.

That's why I'm going to help you understand when full service is - and isn't - the right choice for you.

A "full-service" manufacturer of remote monitoring gear doesn't have an exact definition, but there are several common identifiers that indicate you've gone beyond the "discount" or "bare bones" competitors. You know you're buying from a full-service equipment manufacturer if:

Now that we have a working definition of "full-service", what are some of the problems inherent in this approach?

Full-service companies will include tech support and training with your purchase, and won't hit you with "surprise" fees later.

That's preferable if you're like the majority of buyers, but there's obviously no such thing as a free lunch. You have to be paying for these "free" services somewhere.

A "full-service manufacturer" recognizes that when you choose them, you're making a substantial investment. You expect a good experience. Because of this, they will provide you with tech support with no hourly or per-incident charges.

And not only will they offer you this service free of cost, it will commonly be provided by the same engineers who designed the unit you bought. A full-service manufacturer is focused on your long-term satisfaction - valuing you not as merely a customer, but as a client. Their technical support will come from the company headquarters, not some overseas call-center.

Top-notch tech support is excellent (it's among the most common things our clients positively mention about DPS when asked), but great support reps obviously have to get a paycheck.

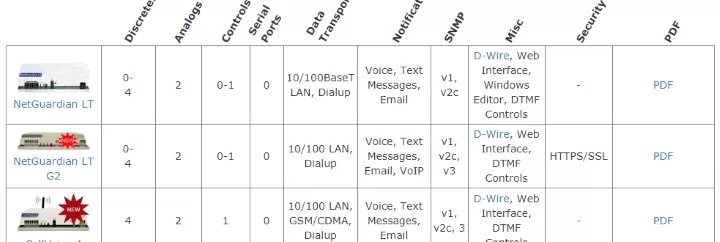

A full-service manufacturer will enable you to make the best decisions when choosing a remote monitoring device or system. They offer a large variety of hardware and software features, so you'll be able to select what fits your specific needs.

Some even go so far as to offer customization of hardware, software, and firmware. If you think you'll benefit from this, look for a company that has their own manufacturing and engineering facilities. Vertical integration is typically the only way to offer customization for reasonable quantities and with a reasonable turnaround time.

Full-service manufacturers will help you if you have unique requirements that an off-the-shelf product can't accommodate. Some of them are able to design custom-built RTUs and masters that will be the perfect fit for your network.

Custom engineering is a valuable feature, and many remote monitoring units which are sold today exist because one customer had a need which no one had previously addressed. The manufacturer was able to do the research and development to make a new feature, or a whole new unit, a reality.

A big product catalog and the option for hardware/software customization allow you to choose your "perfect fit" solution rather than having to settle for an off-the shelf cookie-cutter solution (which most likely will have features that you don't need and will never use). You'll work with engineers who are experienced in the field, and who will help you determine precisely what is needed for your monitoring situation.

Again, these people are ultimately getting some of the money you're paying initially to get such high quality for "free".

The best full-service companies are either based in your country or have good representation there. When receiving new orders, they don't have to rely on outsourced manufacturing, so there's no waiting for overseas shipments of dubious quality.

When it's time for tech support, you'll speak with someone who understands you, is available during your local daylight hours, and works down the hall from the product engineers (or is literally one of them).

High-quality, full-service vendors may also provide you with free training after your purchase, giving your techs more hands-on experience. These classes, although recommended and powerful, have to be taught by engineers. These experts, of course, have to get paid somehow.

Full-service companies generally offer you one-time technology licensing. The DPS licensing model, as one example, is fairly straightforward.

When you purchase a software module for a T/Mon master station to enable a protocol - such as ASCII, SNMP or MODBUS - there are no additional charges for monitoring further devices of that type. This means that you can add as many devices as you want. Once you have paid for a module license, it's yours.

A full-service manufacturer will normally offer a voluntary maintenance contract, which will often come with additional benefits which will be of value - even in the likely event that the unit never fails.

Full-service companies ultimately have to bundle some amount for their services into your initial purchase price.

Although paying for higher quality service or product is often worthwhile (especially when we're talking about monitoring mission-critical networks), you may have a tight budget that prevents you from efficiently "paying it forward" with a larger initial investment.

Sometimes, you might just be forced to pay more tomorrow to avoid paying extra today.

The full-service manufacturing model can actually be more cost-effective than you might think.

On average, if you make a competent choice, you'll generally find full-service solutions for 15% to 30% more money than a roughly equivalent product with no included services.

That addition to the price tag covers things you'd otherwise pay for later, like support and training.

It can also (although this isn't true of every manufacturer/vendor) eliminate recurring licensing or maintenance fees.

Yes, some top-dollar manufacturers will happily charge you on both ends (high initial price AND recurring fees), but this shouldn't have to be the case. There are good "buy once and you're done" options out there.

Unlike with full service, discount commodity manufacturers and vendors allow you to save money initially because they're only selling you "no frills" hardware.

They're able to do that by outsourcing materials or parts for their devices, and not specializing in customization. You're getting one of the designs they already have, like it or not. As we all know, it's wonderful when this works out (I'll shell out for custom furniture to get what I want, but it's always better if I can find something I love from IKEA).

Also, although "custom engineering" is valuable if you need features which are unique or previously have not been developed, it will increase your price by some marginal amount. If your needs are simple and typical, then obviously custom engineering is not needed.

Frequently, cost savings in manufacturing can be the result of labor-intensive production in a low-wage country. This is so much a part of modern life that it can be tough to avoid, but you should at least have your eyes open about this. Also, consider whether corporate or government "good citizen" policies limit your freedom to choose the absolute cheapest option here.

As we just learned, the price difference on your initial PO can be something on the order of 15-30% if you choose a commodity manufacturer for your RTUs or master station. Those savings are real and might be something you just have to pounce on if you can't justify more budget right now (or wait until you have more).

The first one charges you per-device. This can be a problem if you have a network that's continually growing - this means that your costs will be continually growing as well.

A second type of licensing is somewhat better: charging you according to the type of device you wish to monitor (ex. Cisco 15454, Genband/Ribbon C15). This is better than absolute per-device licensing, but it's still a complication and expense to consider.

Either of these two license fee types can be recurring (and often are).

Some companies require you to purchase their maintenance contracts, which increase your costs forever on an annual or monthly basis.

In this case, you can end up feeling stuck. You have no alternative if you want to keep using the product. The money you thought you saved starts to get clawed back over time.

A commodity manufacturer saves you money early, even though it generally costs more over time. As you can see, a commodity manufacturer absolutely saves you money today, but there are long-term costs that you need to consider.

Oddly enough, this is precisely the kind of analysis you should be doing anyway - and it can lead to you justifying a higher initial budget (because you can demonstrate the overall long-term savings of full service).

Sadly, broad selection and customization options put some firm limits on the absolute delivery speed you can expect. Let's look at some of the factors involved here.

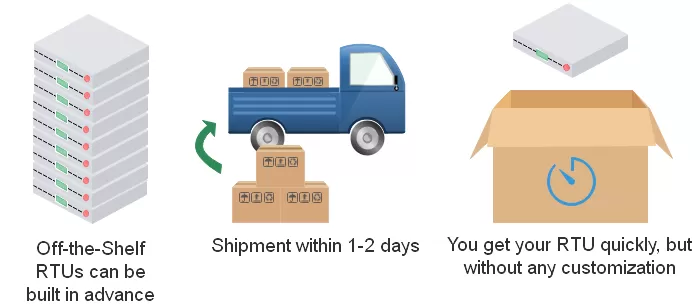

One true advantage of commodity-centric equipment vendors is the fact that, since they probably don't do customization or have a big catalog of products, they tend to stock plenty of inventory in a warehouse. Manufacturing is already done before you even call them, so products can ship within a day or two.

It's easier to maintain an inventory of devices when they're standardized, manufactured at a low cost, and not customizable.

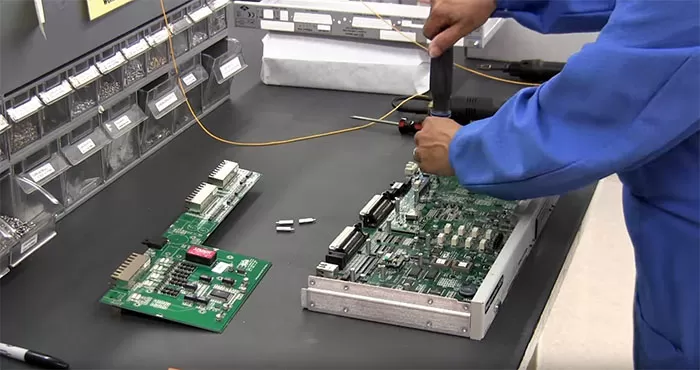

On the other hand, a "full service" company will build your equipment to order. They're responsible for everything, from choosing the right build options (or making something totally custom), building the circuit board, building the aluminum chassis, and assembling the final product.

These manufacturers will be handling your project from start to finish, doing everything from design to packaging. The total lead time from order to shipment might take something like 2 to 4 weeks.

If you absolutely need a quick fix - and are willing to risk a fair amount to get something within a week - getting an off-the-shelf device with zero customization might actually be your best choice.

What makes full-service manufacturers special is the concept of "vertical integration".

This is the practice of handling the entire process of manufacturing in-house from start to finish.

This is actually the core strength of a full-service manufacturer. The quality of the product can be assured. There is no dependence on outside sources.

This works out incredibly well, as long as you choose the right company and everything is running smoothly.

However, if they have operational issues while working on your order, you're in trouble.

Many factors can lead your chosen vendor to trouble: financial problems, natural disasters, legal trouble, or even a simple mistake.

As with everything else, the full service business model has its pros and cons. There are some potential problems to consider.

However, if you are looking for a long-term solution, then a full-service manufacturer is probably the better choice.

If you are more concerned with saving money right now and looking for a "quick-fix" solution to your problem, a full-service manufacturer might not look nearly as attractive as a low-cost one.

Although it is true that you will be investing more money up front, full service tends to save you more in the long run.

A reliable monitoring system will pay for itself in a relatively short span of time in money saved by not having to drive or take a helicopter ride to inspect a site with unclear alarm status. You'll take the right tool and send the right person - or maybe be able to skip the trip entirely with remote control capability.

Another area of savings is in the longevity of a high-quality remote monitoring system. One of the reasons for the higher initial cost of a full-service manufacturer is their commitment to quality.

This commitment to excellence results in robust units which are often still working 20 or more years beyond the time of purchase. Most often, units are replaced not because they break down or stop working, but rather, to be replaced by a newer device that supports newer protocols and standards.

Although the quick-fix low-cost solution may seem budget friendly, in the long run it will almost always prove to be more costly.

You'll see more downtime in your network when your system fails to alert you of impending disaster. Technical support will be an ongoing expense. The replacement of low-quality units later (including those that requires repairs more expensive than the value of the units themselves) will also happen sooner.

Sadly, many clients who had considered a full-service manufacturer solution and were turned off by the cost eventually realize their error. They suffer for a while with the consequences of having made a shortsighted decision.

When considering an investment in a monitoring system to protect your revenue-generating devices, it is wise to consider the consequences of making the wrong choice.

The best way to make sure you'll be happy with your monitoring device - and post-purchase services - is to do your homework.

When putting together a budget for your remote monitoring system, it's important to make sure that you're taking into consideration other costs which might be waiting hidden beyond your preliminary purchase.

Research the facts and take into consideration the advantages and disadvantages of any company before making your final decision. Ask for referrals and case studies. Really dig in and do your due diligence.

As I mentioned at the beginning, I work for DPS. We're a full-service manufacturer of remote monitoring.

Obviously, we think we've found a good way to serve the thousands of companies and agencies who use our products. But that doesn't mean you have to do the same.

Because we're a full-service provider of alarm monitoring gear, you can call us and talk to us! We'll help you think about all the relevant considerations, even if you never buy anything from us.

Give me (or anyone else at DPS) at call today. It couldn't hurt to have a quick discussion.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...