Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen utility power fails, most telecom sites rely on a -48V DC battery plant to keep essential systems running. DC-powered network gear typically stays online. The problem appears when a single rack of AC-only equipment - such as virtual servers, firewall clusters, or data storage - loses power because a legacy UPS cannot sustain the load long enough for generator stabilization.

This was the exact challenge faced by a municipal broadband provider operating a small but expanding network. Despite having a robust 16-battery -48V DC system capable of supporting most of the site for up to 18 hours, one critical rack still depended on 120V AC. During outages, that mismatch exposed the network to unnecessary downtime and operational risk.

Their objective was simple: eliminate the AC power gap without replacing functional equipment or increasing dependence on aging UPS systems.

A legacy UPS is often used to support AC-only devices in telecom environments. Over time, UPS batteries degrade, runtime decreases, and maintenance requirements increase. During extended outages or delayed generator startup, the UPS becomes a single point of failure.

For this network operator, the impact was clear:

As the network expanded, each outage affected more services and more users. The risk scaled with growth.

They knew they needed something better - something that would let them power AC-only equipment using their reliable -48V DC plant.

If you've faced this problem yourself, you've likely explored a few options:

This is often quite impractical. The client had already started buying DC power supplies for newer Cisco UCS servers. But replacing everything overnight was far too expensive - and unnecessary for equipment still within its service life.

A bigger or newer UPS is just kicking the can down the road. Batteries still degrade, maintenance costs rise, and it doesn't solve the mismatch between power sources.

While important and usually not a problem, you can't always guarantee your generator will start up - or that it'll be ready before your UPS gives out.

What this client really needed was a way to convert their available -48VDC power into clean, reliable AC power - right at the rack.

In the ideal scenario, at your site:

That's the kind of system our client wanted. And that's what we delivered, using custom-sized, rack-mounted DC-to-AC inverters that turn your existing power plant into a full-site power solution.

Let's take a closer look at what we provided - and how it can work for you.

The target operating state was defined clearly:

This was achieved by deploying rack-mounted DC-to-AC inverters that convert existing DC power into stable AC at the rack level.

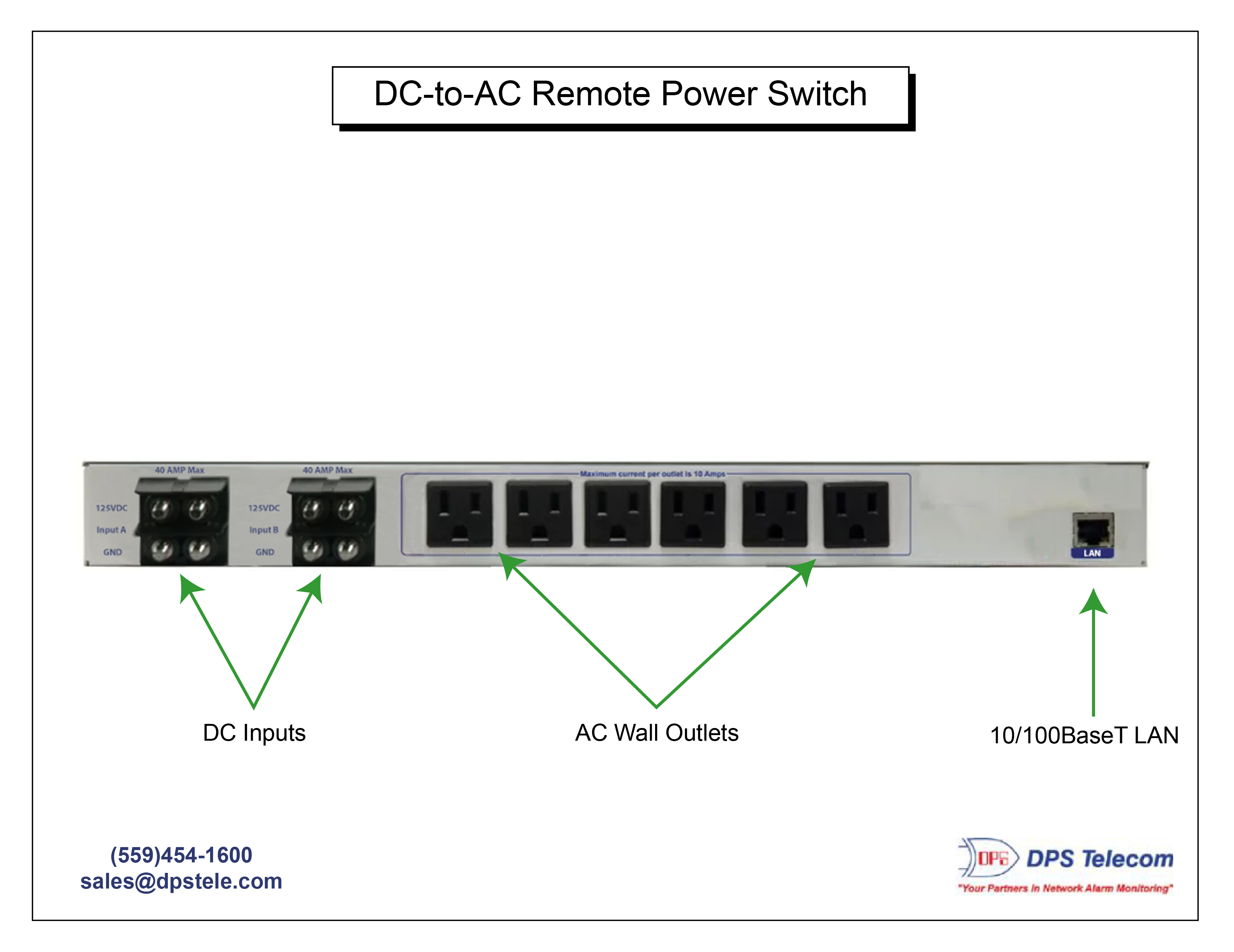

DPS Telecom engineers DC-to-AC inverters specifically for telecom and critical infrastructure use cases. These systems are designed for continuous operation, predictable loads, and integration into existing racks and power architectures.

These aren't the plug-and-play devices you'd find in a big-box store. They're rugged, rack-mounted units built to run mission-critical systems under real-world conditions.

For this client, we designed a system with the following specs:

We don't believe in single points of failure. By using dual DC inputs, we provided built-in redundancy - so even if one DC feed goes down, power conversion continues uninterrupted.

This site had plenty of rack space, and we optimized our inverter footprint to fit neatly into their existing 52RU racks. This avoided any awkward shelves or DIN rail improvisation. Indeed, there was just a clean, secure installation.

The client's most demanding device - their data store - needed over 1000W. We matched that requirement, with room to spare. Other AC loads, like firewalls and legacy servers, had lower power needs and easily shared the same unit.

Rather than forcing a "one-inverter-per-device" model, we provided multiple AC outputs per inverter. That allowed the client to run several devices from a single unit - saving rack space, cost, and complexity.

As they transition more equipment from AC to DC, their inverter needs will shrink. And that's fine. Our gear scales with your operation - whether you need a single unit or a dozen.

Since we custom-build for each application, we ensure the right balance of capacity, efficiency, and safety.

This customer had prior experience with DPS Telecom monitoring equipment and understood the value of tailored engineering. Instead of deploying generic power electronics, DPS adapted proven inverter designs to match real-world constraints such as voltage, connectors, and load requirements.

The result was a practical bridge between AC-only equipment and a DC-native power infrastructure - without introducing new operational complexity.

At DPS, nearly every project starts with a conversation and ends with a custom fit.

As our sales engineer explained during the call:

"A lot of things we do start with an existing design and we change 10% - maybe it's a voltage tweak, different connectors, or bigger relays to support a larger load. That's how we match real-world specs, without starting from scratch."

In this case, the client needed a bridge - a way to run their AC-only rack from the same batteries powering the rest of the site. We delivered exactly that.

Power conversion solves only part of the uptime equation. Visibility into power and environmental conditions is equally important.

The customer identified monitoring gaps across several sites, including limited visibility into:

Past incidents had gone unnoticed until a technician visited the site. Standardized monitoring using DPS Telecom RTUs allows operators to detect and respond to high-impact risks before they cause outages.

Let's break down the value proposition for inverters like these:

Your -48V battery plant is long-life and designed for telecom-grade backup. Why not use it for all your gear?

Take advantage of having less maintenance and lower replacement costs. This means no more surprise outages when UPS batteries fade.

These aren't band-aid solutions. With durable hardware and custom specs, these inverters will serve your site for the long haul.

Use one unit today. Add more as needed, or remove them gradually as you fully convert to DC.

Compare that to the cycle of buying and maintaining UPS systems - or replacing all your gear with DC-compatible versions - and the economic case is clear.

This project began with a single operational question:

Can AC equipment run reliably from a -48V DC plant?

With the right inverter design, the answer is yes.

DPS Telecom helps network operators reduce downtime by addressing real infrastructure gaps - whether through DC-to-AC inverter systems, remote monitoring with NetGuardian RTUs, or centralized visibility using T/Mon master stations.

Call: 559-454-1600

Email: sales@dpstele.com

Share your site layout, equipment mix, and runtime requirements. DPS Telecom will help you design a solution that keeps both AC and DC systems online - using the power infrastructure you already trust.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...