Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you've managed your network for a few years, I guarantee you know this frustration: You get your network monitoring system fully setup and configured, just to find out one of the monitored elements is no longer being manufactured or supported by a vendor. Now what do you do?

In a perfect world, units would always be supported whether they're still being manufactured or not. But, for most manufacturers, supporting legacy equipment for more than a few years is not the reality. Once a product is no longer being made, it's usually no longer being supported as well. This can be a huge pain and can get expensive quickly. You never want to be replacing older generations with newer ones every other year.

Wouldn't it be nice to buy and install a product that's perfectly designed for your network? Also, wouldn't it be nice to have a product designed to last for years. Think of the relief you would feel knowing you've invested in a product that would always be supported no matter what. Imagine free tech support with industry expert engineers, too. That's the dream...

...And the reality here at DPS. Our team can design and manufacture just about anything, and as long as the unit is still running, we'll provide support for it.

With supply chain issues rising more and more, customers like you, are coming to us with one particular problem. You might an improved replica of a product that's a critical component to your already established network, but is no longer being supported.

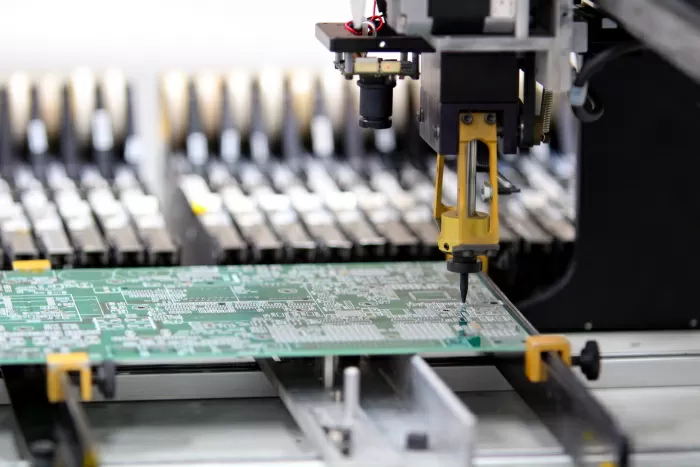

Because we're vertically integrated, each piece every product is hand-built at our headquarters. That makes product development that much faster and robust.

The first step in developing a new product based on another company's existing product is research and development. For example, a transportation company recently asked for us to design a unit equivalent to their audio/PTT distribution panel. We were able to get our hands on an existing unit, which was ideal and always helps (but don't worry it's not required).

The design of any new product starts with our ECAD department extensively researching the existing product to learn the features and applications. They take apart the unit (physically or by reviewing the spec) and get down to the component level.

They'll then begin the PCB design layout, test components to ensure their functionality, and analyze the placement of each piece at the board level.

While developing the ADP, one of our engineers had to deconstruct the audio/PTT distribution panel to see what the unit did and didn't do. He had to reverse-engineer the product to design the schematic for the PCB. He hand-drew the components he could see on the board onto a piece of paper. Looking at some components with a magnifying glass, he determined what each element was - and what else that component was connected to. He then researched each component to make sure he had identified it properly. It was a lot of work, but necessary for development.

At this stage in the process, our Engineering department will begin programming both the back-end and front-end necessary for the functionality and user interface of the product.

During this design stage, our Engineering and ECAD team will work closely together to produce a working prototype as quickly as possible. They'll cycle through multiple iterations rapidly by analyzing the design and functionality at every stage of development.

The final step in the design phase involves our ECAD team. They'll design the metal chassis that will enclose the unit once it's completed.

Using the PCB layout our ECAD department provided, the manufacturing team will get started developing the product. Most of our manufacturing team has been with us for over 10 years, so building and testing new equipment is second-nature to them. This ensures your fully customized product is being built to the highest industry standards.

Across the street at our Metal Shop, the team will cut, bend, attach hardware, and paint the metal chassis. Because we cut our metal in-house, we can match the look of the MFD product. If you prefer, you can request exact dimensions for the enclosure and a specific silk screen color.

Once everything has been built, we vigorously test the unit for more than 24 hours. We try to break it by power cycling it repeatedly throughout the night. We also do isolated hardware and software tests to make certain the unit is functioning properly.

For new product platforms, we prefer to do a field trial with you. This will give us an opportunity to get your feedback and implement any modifications while we're on site with you.

Field trials usually are a bit rocky in the beginning of the week. We're hooking the unit up for the first time and using it in a real-world environment. We learn the various ways that our best-guess design just doesn't cut it. This always hurts a little, but that's exactly why we do a field trial in the first place. The rest of the week, we'll work with you to get the all new unit's kinks worked out. This leaves you with a perfect-fit solution.

Being a part of the development process gives you the opportunity to get exactly what you want out of your customized monitoring solution. Your wish-list unit becomes a reality.

Our CEO, Bob Berry, says it best: "The key to getting the most value out of DPS is to make us part of your design team. This ensures you get a perfect-fit solution that solves your exact problem."

Because we want you to come back to DPS again and again, we also have a 30-day money-back guarantee. If you have any issues, our tech support team is here to help you over the phone any time of the day.

Give our sales department a call to start today. We'll start designing your custom unit right now. We just need a few pieces of information to get started:

If you're unfamiliar with these terms, don't worry. All you need to do when you call DPS is tell us what you're trying to accomplish. Let's make your monitoring dreams a reality today!

Give me a call at 559-454-1600 or email me at sales@dpstele.com

Cara Doswald