RTU-PLC Tutorial: What you Need to Know

Remote Telemetry Units (RTUs) and programmable logic controllers (PLCs) both perform the same basic function: remote alarm monitoring and control of remote equipment. How they go about doing that job, however, varies significantly. This makes RTUs better for some environments and PLCs better for others. In this tutorial, I'll help you understand these differences and how they apply to your project.

Which monitoring device you choose is perhaps most heavily related to your industry. There are no guarantees that a certain industry will be best served by an RTU or PLC, but this tendency exists because each industry has common structures and procedures.

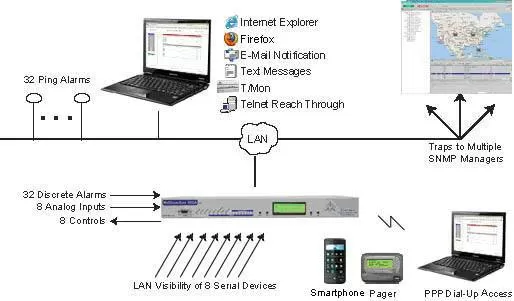

Deploy an RTU to monitor and control critical points in your network.

Deploy an RTU to monitor and control critical points in your network. For example, PLCs are generally found to be quite useful in manufacturing environment, thanks to the following characteristics:

- Manufacturing is contained within a relatively small area

Although any RTU/PLC could be used in a small area, a PLC has the advantage here because one big RTU advantage - aggregation of multiple inputs/outputs on a single communications channel - is rendered unimportant. In a confined space, you can connect each individual PLC to your network individually without wasting many resources. This makes the low-price advantage of PLCs worth the cost. - Manufacturing has environmental controls

With some exceptions (superheated metal processing, for example), most manufacturing processes have humans in and around the production line. This means that any extreme high or low temperatures must be controlled. This makes PLCs, which are generally not environmentally hardened like a good RTU, a viable option. - Manufacturing already uses PLCs most of the time

Even if the reasons above did not exist, existing infrastructure would still dictate a healthy amount of your RTU/PLC decision. You probably don't have the luxury of performing a 100% swapout of your SCADA/monitoring system, so you'll need to integrate with what you have. Unless you have a good reason to deploy RTUs into a PLC environment (and there are some good reasons), you'll benefit by deploying PLCs that are similar to what you already have out there.

Similarly, RTUs are commonly associated with their own set of industries. They are generally deployed into industrial telecom networks (used by telecommunications companies of all kinds, transportation companies like railroads, government entities like police and fire departments, and others as well). Again, there are several reasons why this RTU preference exists:

- Industrial telecom networks are geodiverse (spread across a large geographic area)

Unlike in manufacturing, you simply can't home-run multiple PLCs at one distant remote site, which may be hundreds of miles away from your central office. Just like structuring an organization, you need a taller technology hierarchy for this network configuration. With an RTU, this is accomplished by a single unit that can handle the functions of a dozen or more small PLCs at a remote site. Since an RTU is one box with one communications interface, one chassis, one power supply, etc., you will create an economy of scale by deploying an RTU. - Industrial telecom sites often have no/limited environmental controls

Telecom sites can be extraordinarily remote and harsh. From a snowed-in site on top of a mountain to a simple equipment cabinet in scorching desert heat, gear in these environments must be able to handle a wide temperature range. RTUs, again, have an advantage here over PLCs. In a self-reinforcing cycle, RTU use at telecom sites demands a wide temperature range, which leads to more deployments and product development. - Telecom equipment must last longer before failing since consequences are greater

In a manufacturing environment, failure of your monitoring and control system isn't a huge problem. You can quickly reach the site of the failure to minimize the length of any operations disruption. In telecom, it's never that easy. Some sites require snowmobiles or even helicopters to reach during the winter, and even accessible sites can take hours to reach by truck. RTUs are designed to deliver high reliability to avoid expensive and time-consuming repair trips.

View all RTUs...