Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayAny organization with critical infrastructure faces an ongoing challenge: how do you keep up with evolving technology without disrupting your existing operations? And how do you do all of that without destroying your budget in the process?

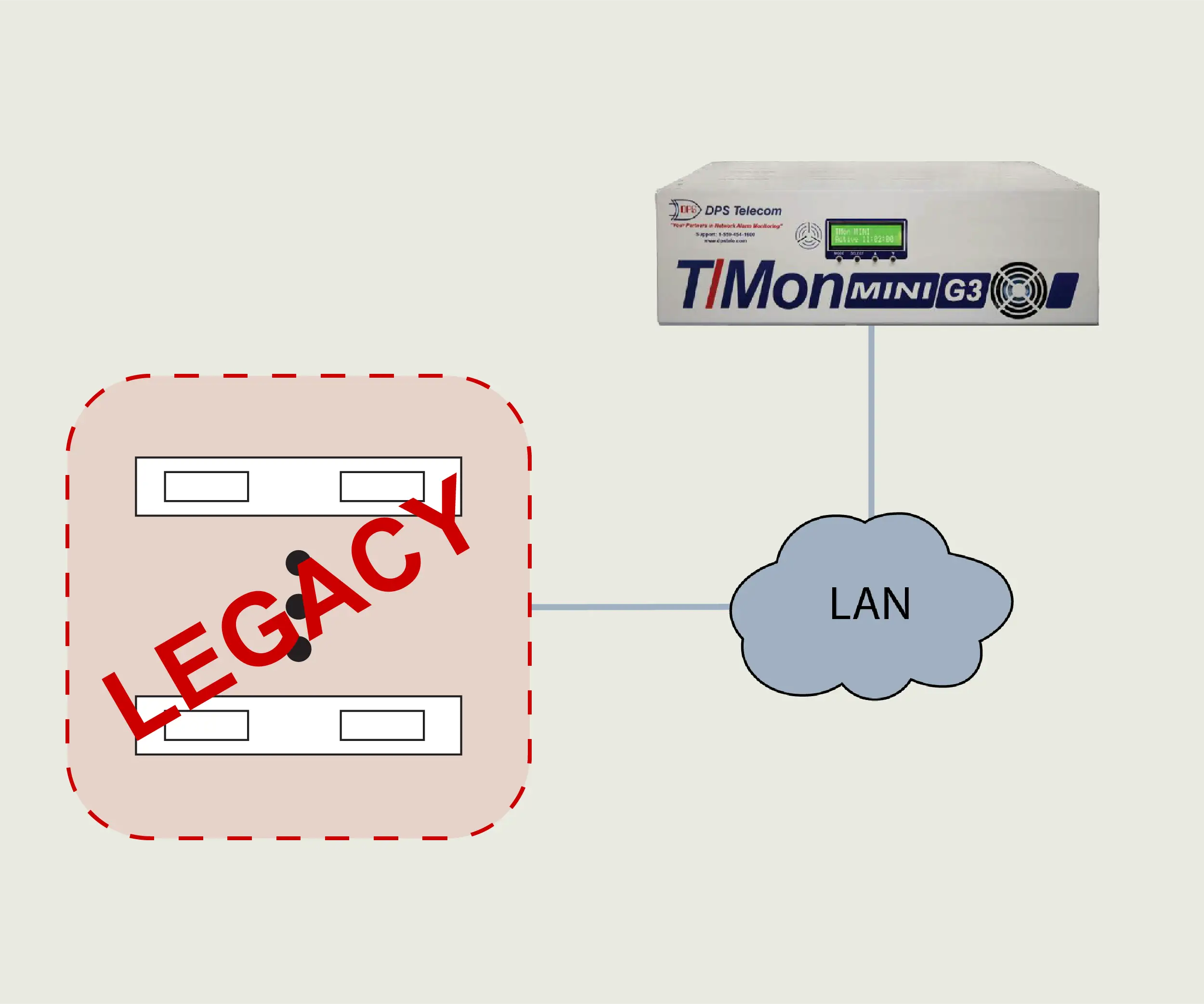

Recently, a long-time client reached out for help with these challenges. They had made a partial jump from legacy DOS-based monitoring screens to a T/Mon MINI master station in 2023. However, their evolving microwave and radio systems demanded even more modern integration.

Their journey exemplifies the balancing act that many network operators face when blending legacy equipment with next-generation RTUs and monitoring platforms like T/Mon.

Here's how DPS helped them navigate protocol integration, step-by-step RTU upgrades, and a shift toward a fully modernized monitoring ecosystem. By reviewing this client's successful path to a solution, we'll touch on how these lessons can help you tackle similar challenges in your own network.

For years, this client relied on outdated DOS-based T/Mon screens, even though newer options had been available for over 10 years. Although their 2023 upgrade to a T/Mon MINI G3 introduced a more intuitive interface, some lingering integration issues meant they had to juggle multiple interfaces for configuration.

Managing multiple interfaces isn't an uncommon problem when you make a partial transition from old to new. It can feel like you're trying to merge two parallel universes - one stuck in DOS, the other living on the modern web.

With fresh expansions on the horizon (including a brand-new Harris P25 radio network and MNI's Proteus MX microwave equipment), they knew the time had come to build a fully integrated monitoring strategy.

The client's new microwave and radio projects created a pressing question: Would they be able to gather detailed alarms via T/Mon (using the native protocols of the microwave and radio gear) - or would they have to fall back on simple dry contact closures?

They were also considering a three-site expansion that would require new RTUs. Should they continue using older models of DPS RTUs or upgrade everything to the newer G6 series?

A big piece of the puzzle was confirming whether DPS already supported SNMP for MNI's Proteus MX and if the Harris P25 system would require custom development. Protocol support wasn't just a checklist item here. It was the key to getting rich alarm data (instead of a handful of binary on/off alerts) for better troubleshooting.

As this client added new sites, they worried about having to train staff on multiple RTU web interfaces - some older, some newer.

Having one set of procedures for legacy equipment and a different set for new equipment increases the chance of mistakes (and frustration).

One of the biggest topics we discussed with this client was how to move beyond basic on/off alarms for their new MNI Proteus MX microwave platform and Harris P25 radio system.

When you rely on dry contact closures, you lose the detailed alarm data that modern protocols provide. Instead of a non-specific "something's wrong" alert, SNMP can deliver details like performance thresholds and fault codes. It can even provide contextual information about what's happening on the device.

With T/Mon's protocol mediation, it becomes possible to integrate SNMP alarms from Proteus MX directly into a centralized monitoring system. That means:

And if (or when) additional protocol development is required for the Harris P25 system, DPS is ready to create a custom device module - just as we've done for hundreds of other client-specific needs.

Another concern the client raised was the logistics of adding new RTUs without disrupting their existing network. Their current NetGuardian 864 units have served them well for years. So how do you add G6 RTUs for new sites - without forcing a rip-and-replace on older sites?

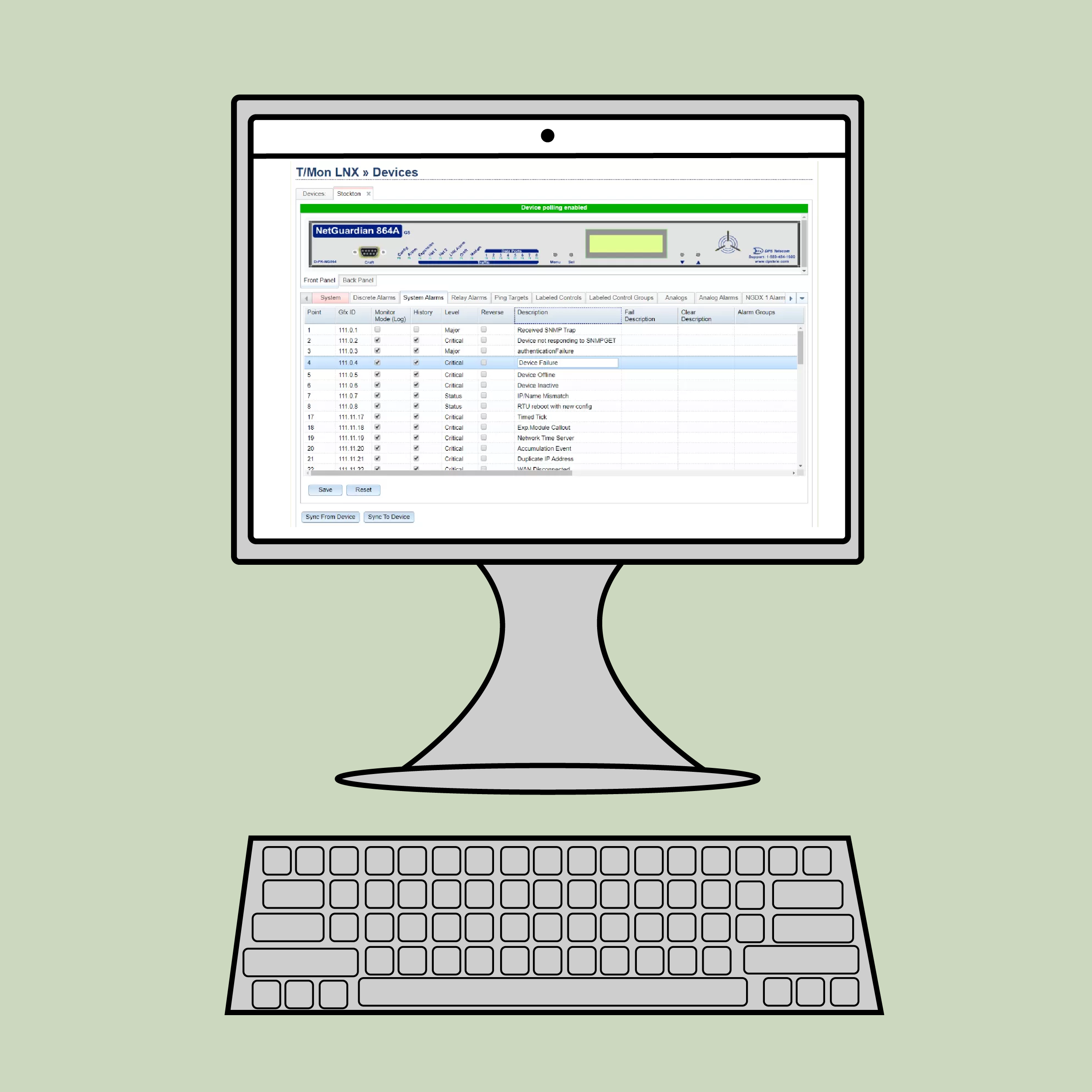

Fortunately, T/Mon is designed to simultaneously handle different generations of DPS RTUs. You can deploy G6 RTUs in your new locations while running older devices at your established sites.

Since T/Mon supports both older and newer generations of RTUs, you don't have to do a full cutover all at once. This way, you maintain visibility across your whole network, and you can manage your upgrades on a more comfortable timetable.

The client's end goal - and maybe yours - is a monitoring setup that is fully integrated and works intuitively:

In short, they wanted to protect their existing investments while stepping confidently into the future.

The NetGuardian 864A G6 takes the core functions that have existed in the NetGuardian line for 20+ years and adds important modern functions:

If you're serious about preparing your network for the future while keeping installation overhead low, the NetGuardian 864 G6 offers a high-performing and cost-effective solution.

DPS has a long track record of building custom device modules that solve real-world protocol challenges.

The client's three-site project is only the beginning. As they continue to scale, they need a monitoring setup that can evolve with them. T/Mon can handle thousands of alarms if needed, and the G6 RTUs offer flexible I/O that can adapt to each new site's distinct configuration.

Investing in a scalable solution now means you're laying down a solid foundation for reliability well into the future.

After speaking with DPS, the client received a tailored proposal that mapped out:

Armed with this info, they can make an informed decision - without worrying that they'll be boxed into a corner in a year or two.

If you're looking to modernize without leaving behind the gear that still works, here's what you should remember:

With DPS Telecom's combination of custom protocol support, backward compatibility, and top-tier product development, you get a partner who won't force you to choose between old and new. You can have it all.

Are you stuck with old alarm equipment or bracing for a major network expansion? Let's figure out the best path forward together.

Give us a call at 559-454-1600 or shoot us an email at sales@dpstele.com. We'll get you a detailed proposal that outlines the exact hardware, software, and protocol support you need for a smooth transition.

I can't wait to hear about your project - and help you build a network monitoring strategy that can handle anything you throw at it.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...