Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayOne major broadcaster told us recently:

"We've got diesel backup generators at our tower sites - but no way to actually monitor fuel levels. We've always just crossed our fingers and hoped for the best..."

Does that sound familiar?

That's exactly the kind of challenge we hear all the time. Like many in telecom, broadcasting, utilities, and public safety, this client was operating remote sites powered by diesel - but had no electronic visibility into how much fuel was in each tank.

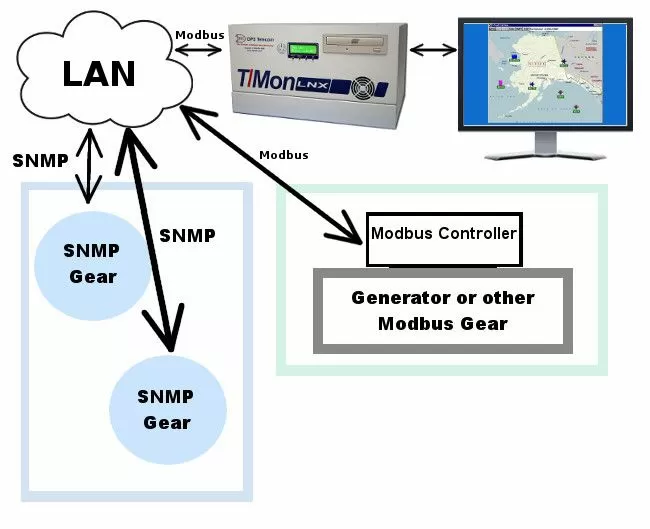

And while they were already using SNMP-based remote monitoring systems, they couldn't find a fuel sensor that integrated cleanly.

That's when they found a solution via DPS Telecom.

I'll about to break a few key details down for you:

This client operates multiple radio and TV broadcast towers, each backed by a diesel generator. During blackouts, those gensets are the only thing keeping signals in the air.

But despite that critical role, they'd never had a reliable method to monitor fuel levels remotely.

Like many others, they were relying on a combination of:

They had plenty of motivation to fix this, but they were also realistic. They didn't want to overhaul their entire infrastructure to do it.

And here's the twist: They were already running SNMP-capable RTUs at every site. They didn't need an entire new system. All they needed was a sensor that could connect to the equipment they already had.

That's where most "modern" solutions fell apart.

Like many others in their position, the client did a lot of online searching for fuel sensors. What they found was disappointing, as they kept running into:

Many fuel-monitoring systems route data through cloud servers. That's fine for some, but not for clients who already have secure, on-prem SNMP networks.

This broadcaster's SNMP gear already had a web interface. They didn't want extra infrastructure - or new attack surfaces.

Some solutions require LTE or 5G data plans to send fuel readings. That's another monthly cost, another failure point, and another device to provision.

For a team that had already invested in wired IP infrastructure, this didn't make sense.

Many companies don't actually sell sensors. They sell platforms. You can't just buy a float sensor or analog output. You have to buy their full base unit, along with access to their cloud dashboard.

This completely ignores you if you already have RTUs, masters, and SNMP software.

Fortunately, our client in this case had a clear idea of what to buy and install.

What they wanted was a simple diesel fuel sensor that provides a 0-5V or 4-20mA analog output, or (ideally) native SNMP or PoE support. They wanted this sensor to be able to be installed without removing their existing gauge, plugging directly into their current RTUs.

If the tank dropped below 25%, they wanted an alarm - that's it. There was no need for cloud servers, new dashboards, or monthly fees.

They just needed a basic sensor that integrates with the system they already trusted.

And we were happy to help.

At DPS, we've been building remote monitoring hardware for over 30 years. Our team knows RTUs, SNMP, analog signals, and how to bridge the gap between different generations of equipment.

We understood that this client didn't need a new RTU. They needed a diesel fuel sensor that could connect to their current gear.

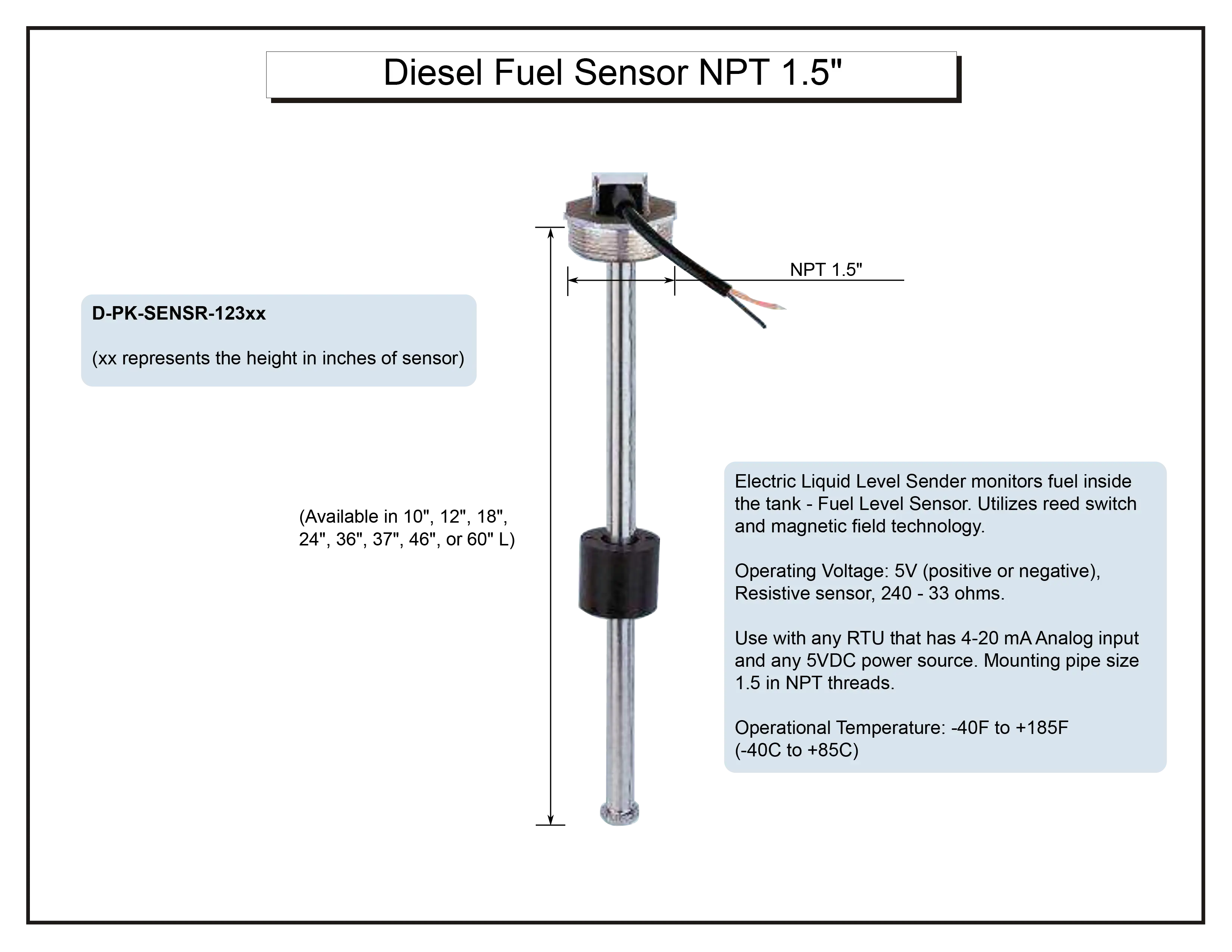

So we recommended a sensor from our standard line - one we often bundle with our NetGuardian RTUs:

This sensor works well for several reasons:

With this sensor, the client didn't need to replace anything. They could simply install the sensor, wire it to their RTU's analog input, and begin receiving actionable data.

Another concern here was whether the client would have to remove their manual float gauge to install the sensor.

The answer? Not at all.

Most above-ground diesel tanks - especially those used with gensets - are built with multiple threaded NPT ports. These ports (1.5", 2", etc.) are used for:

According to industry guidelines and firsthand DPS experience, it's very common for tanks to have more than one available port.

So yes, you can install a new electronic sensor without removing the existing gauge. You just choose an available port and install the unit using the appropriate threaded adapter.

This sort of technology is especially important for propane tanks, since propane boils at room temperature. Being able to swap out needle gauge for a machine-readable one is a similar process, but that's a topic for another blog post on propane monitoring!

Before ordering any sensor, make sure to gather:

The sensor needs to roughly match the fuel height inside the tank. It's okay to undersize slightly, but too short will reduce your reading range. Too long of a sensor won't fit.

Pro tip: measure from the top NPT port to the bottom of the usable fuel tank.

Check the diameter and threading on the available NPT ports. Most of our sensors are 1.5" NPT, but other options (like 2") are available upon request.

Bring a ruler and take clear photos of the tank's top (ex. gauges and ports) during your site survey.

Does your RTU support:

We can match the sensor to your RTU's input specs.

If you're unsure, send us your RTU make and model. We've probably worked with it before.

Most of our sensors require 5VDC input. If your site runs on AC or -48VDC, we can recommend a simple converter.

The client also asked a great question:

"Do you have a PoE diesel sensor that outputs SNMP directly?"

While DPS focuses on sensors that integrate with our RTUs (which then output SNMP), we understand that some clients want standalone SNMP fuel sensors.

That's why we also helped this client evaluate a few third-party options.

These devices may be useful if you don't already have analog-capable RTUs, or if you need a "black-box" system that's fully self-contained.

Still, we always advise caution: most of these solutions require installing their proprietary gateway and only support their own sensors.

So unless you're looking to add a completely parallel system, the analog float sensor is often the cleaner option.

In this case, the client walked away with a simple, powerful plan:

With this plan, there are no monthly fees and no new dashboards. There's only reliable, real-time data flowing into a system they already trusted.

At DPS, we believe in empowering clients to make the most of what they already have.

Sometimes that means designing a complete system from scratch. Other times, it means recommending one well-matched sensor and getting out of the way.

We're not here to push hardware you don't need.

We're here to help you:

If you're interested in integrating diesel fuel sensors into your current system - or just want help figuring out what to measure - we'll guide you through it step by step.

Call us at 800-622-3314

Email: sales@dpstele.com

Tell us:

We'll give you a clear recommendation, with no fluff, no sales pressure (our "sales team" is mostly staffed by engineers), and no unnecessary gear.

When a blackout hits, you want to be the one who already knows there's fuel in the tank.

Let's get your site ready - before the next storm rolls in.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...