Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIn applications such as boilers, furnaces, and other industrial combustion equipment, you will hear the term "combustion process". When speaking about a combustion process, you might hear the term "oxygen trimming".

Oxygen trimming is used to optimize fuel efficiency and reduce your emissions. This is done by using real-time measurements to then control the air and fuel ratio.

Getting the right air-fuel ratio is crucial for efficient and planet-friendly combustion. If you use too little air, you won't get a complete combustion and you will produce harmful byproducts (such as carbon monoxide). On the other hand, using too much air will increase carbon monoxide and make your fuel usage less efficient.

Sensors allow you to keep monitoring your oxygen in flue gas. When the sensor detects certain feedback, the airflow rates and fuel flow adjust to maintain the air-to-fuel ratio.

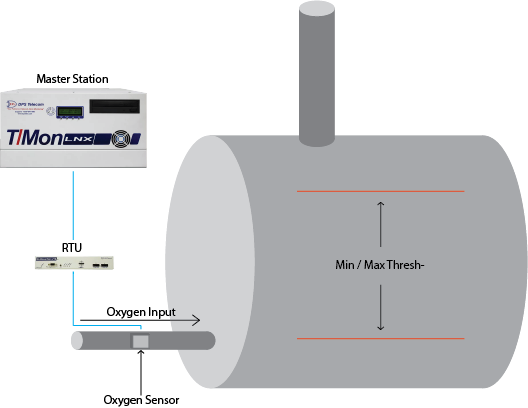

A good way to automate this process and make it easy to maintain is through SCADA (Supervisory Control and Data Acquisition) such as RTUs (Remote Telemetry Units) and Master Stations to receive and send data all from one convenient place.

Use the following configuration to achieve automated and monitored oxygen trimming:

Once you have set up the initial monitoring and control of oxygen trimming, it's time to focus on data analysis. Take a look at your logged data and highlight patterns that can be either cut out or taken advantage of.

Your master station and RTUs assist in establishing minimum and maximum thresholds for your oxygen-trimming process. This allows you to fine-tune your emissions and identify any issues that may arise.

Let's explore how you can optimize your performance using SCADA and HDMI:

Not all maintenance is about preventing issues. Sometimes, maintenance is necessary because something went terribly wrong, causing the facility to lose time, labor, and money. It's important to stay proactive by conducting regular equipment check-ups instead of waiting until it's too late and the damage is irreversible.

Find a manufacturer that can equip you with a SCADA system that lets you foresee patterns that lead to the following issues:

Support your in-house staff by providing them with tools that make their job easier, enabling them to work efficiently and effectively. A user-friendly HMI (Human-Machine Interface) will require less training time.

When your in-house crew is supported with an easy-to-read HMI, they will make the right decisions with enough speed because they are confident that they are receiving and interpreting the right information.

One way to do this would be an advanced SCADA HMI that displays graphical representations of all your alarm statuses across your few or many facilities on one screen. A good manufacturer understands that you need to have an intuitive interface that lets you know where your problems are precisely, and what they are.

Look for the following things when looking for a SCADA manufacturer that can supply you with a good HMI:

This will prevent back-and-forth car trips that take up your staff's time and your money in an attempt to just find out what tools you need to fix your problem.

Find SCADA system manufacturers that keep you compliant with your area's codes. This can include the following codes:

To ensure a compliant SCADA system installation for your industry and location, it's crucial to consult with the right experts. This includes engineers, safety professionals, and regulatory authorities who can guide you through the maze of codes and standards. Don't overlook this vital step!

DPS Telecom is a SCADA system manufacturer that allows you to grow and expand at your own rate while providing you with the same premium monitoring capabilities from day one. At DPS, we offer you the same capabilities but at different storage levels and price tags.

For example, we have multiple tiers of RTUs that will perfectly fit your budget, whatever it may be, without compromising your required monitoring power.

We also provide you with site visits, training seminars, and in-depth documentation that allows your in-house technicians and maintenance crew to get you back online in no time in the event of a malfunction.

We also provide you with 24/7 emergency tech support in the event of an RTU or master station failing. Our service and equipment are our reputation, and we want to do it justice.

DPS Telecom offers you everything you need to monitor your oxygen trimming, and we also set you up for success with our 30% off RTU trade-in program so that we can nurture a long-running relationship.

Although our RTUs end up being replaced due to newer technology being available instead of a device failure, we will trade your older RTU for a new one for a 30% discount no matter the condition.

If you would like to know more about how we can fully monitor and service your oxygen trimming with our SCADA systems, or if you have a similar but different application that you think we can monitor for you, give me a call now.

In the unlikely event that we can't find a solution working together, I will still do my best to point you in the correct direction

Call today at 1-800-693-0351 or E-mail me at sales@dpstele.com

Ziad Alezabi

Ziad Alezabi is a Application Documentarian at DPS Telecom. He reviews successful DPS client projects and reports on the best practices that you can use to successfully reach your own project goals.