Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhat if your current monitoring setup is hindered by legacy equipment, patchy internet service, and devices that are just hard to configure?

Your facilities are packed with critical gear. This includes telecom infrastructure, public safety radios, FM/TV broadcasters, and equipment racks leased out to multiple tenants. You have to protect them.

That's exactly the challenge one recent DPS client was facing. Like many others, they wanted better visibility into power and cooling systems, but were stuck using monitoring gear that hadn't kept up with the times.

See how a modern RTU-based monitoring system is solving their power and HVAC headaches - without overcomplicating the process.

This client was managing 10 sites, each with a mix of:

The primary internet connection was a radio ISP, which cut out with zero warning.

To make things worse, the older monitoring equipment:

As a result, they had little to no real-time visibility during power outages, HVAC failures, or generator faults. And that's exactly when monitoring is needed most.

It's tempting to hang onto older systems because "they still work." But as the client admitted, they had simply put off replacing their legacy systems for years due to other projects.

That decision was costing them in 2024, and it might be costing you too:

Radio-based internet service was the primary link to many of the client's remote sites. Unfortunately, it was cutting out frequently, leaving them blind.

Switching to cellular seemed like the obvious next move, but they hit a roadblock: fixed/static IP addresses.

Many cellular carriers don't know how to handle requests for fixed IPs or they make the process overly complicated. That made the transition feel daunting.

The old system's setup process was described as "Boolean" and "frustrating." Making even basic changes required working through nested logic and unfamiliar syntax.

With today's staffing shortages, training someone on an overly complex system just doesn't scale.

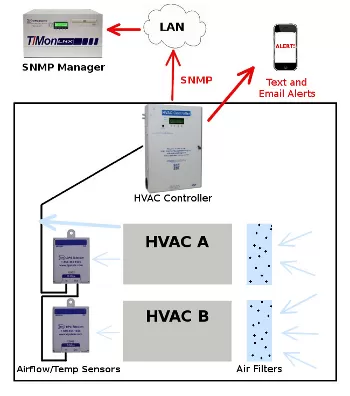

The client wanted to monitor multiple voltages (AC/DC), temperature values (battery, engine, HVAC), and airflow states. Their older gear, though, didn't have the analog capacity or sensor flexibility to make that practical.

Some of their HVAC airflow sensors were simple switch closures, while others used resistive temperature probes. The old equipment wasn't flexible enough to support both easily.

Tenants like broadcasters and public safety users often wanted visibility into their equipment environments. But the existing setup didn't offer user-specific web access or read-only logins.

This lack of transparency created visibility holes and extra work for the client.

This client had a crystal-clear vision for their next monitoring system:

Ultimately, they needed a single platform that could do all of this, without requiring weeks of IT configuration or extensive training.

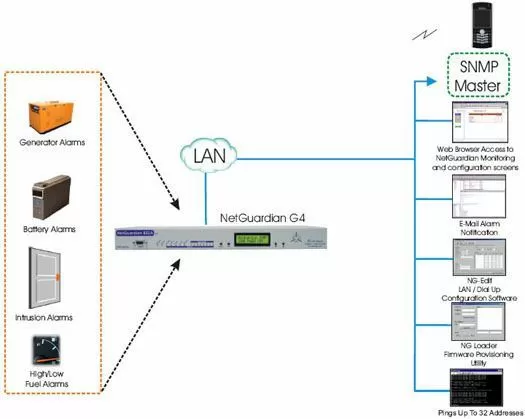

Working with a DPS Engineer, the client explored a monitoring solution built on NetGuardian G6 RTUs, combined with a cellular gateway and D-Wire sensor bus.

This solution directly tackled their pain points with:

Using a DPS-supported RTU and a client-supplied cellular gateway, each site gains a dedicated IP connection. That means no more ISP radios to babysit.

Since the DPS web interface supports dynamic DNS, there's no need for static IPs, making cellular provisioning vastly easier.

The G6 platform offers a clean, browser-based interface for:

No more cryptic setup steps. You just log in, configure your thresholds, and you're done.

The system integrates:

This means the client can fully monitor:

Even better, the D-Wire bus supports up to 16 sensors per chain and has zero impact on traditional analog/discrete capacity.

The web interface supports user profiles with granular permissions:

You can even send email or SMS alerts (via modern low-cost gateways), keeping everyone informed without relying on old pager-style alerting.

With 10 sites, the client was right at the threshold where they could:

Either option is fully supported (and future expansion is simple).

This project was successful because DPS does more than just sell boxes...

We specialize exclusively in remote monitoring systems. That means our gear is:

From cellular integration to analog scaling to user access, every part of this system is designed to make your job easier.

Beyond convenience, there's clear operational value in upgrading your monitoring system:

The net result is fewer surprise failures, faster responses, and happier stakeholders.

If you're stuck with legacy systems, unreliable radios, or confusing setups, it's time to step up.

Let DPS design a system for you that:

We'll build your custom proposal - including diagrams, assumptions, and options - so you can get clarity before you commit.

Call DPS Telecom at (559) 454-1600

Or email sales@dpstele.com

Let us walk you through a real-world solution - just like we did for this client.

You'll get a full proposal with:

Don't wait until another heatwave or power outage exposes the cracks in your system. Let's build a monitoring setup that works 24/7 - so you don't have to!

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...