Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayRemote temperature monitoring systems, also known as temperature notification systems, are most commonly used in telecommunication or IT environments where computer equipment must work with high reliability and high visibility for many years.

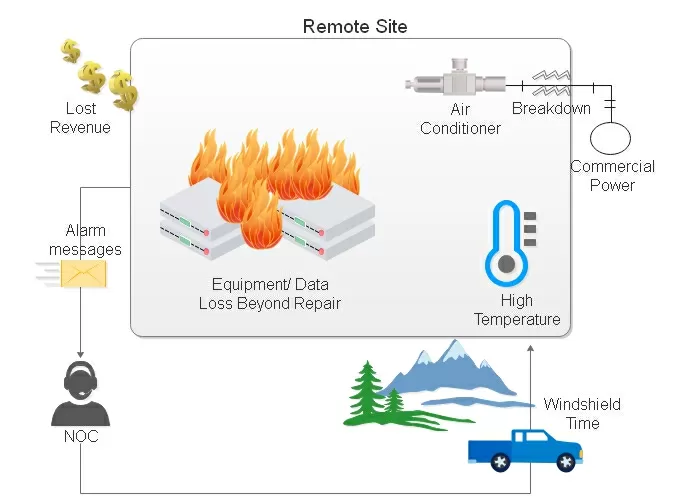

This kind of monitoring protects your network against thermal shutdown, not to mention irreparable and expensive damage to your network. Ultimately, it gives you the peace of mind of avoiding lost revenue that results when systems fail.

While "too hot" is the most common issue when dealing with computer systems, the temperature drop is also a very real problem in some places.

The right temperature monitoring system should allow you to keep track of critical temperatures at all of your sites, server rooms, and data centers that contain important gear. Instead of turning to install new distributed control systems, you'll be able to use intelligence to solve temperature-related problems.

When you think about remote monitoring, words like "protocol" and "alarm output" might worry you; however, unlike direct monitoring of equipment alarms, site temperature is one of the easiest things to keep an eye on from a distance.

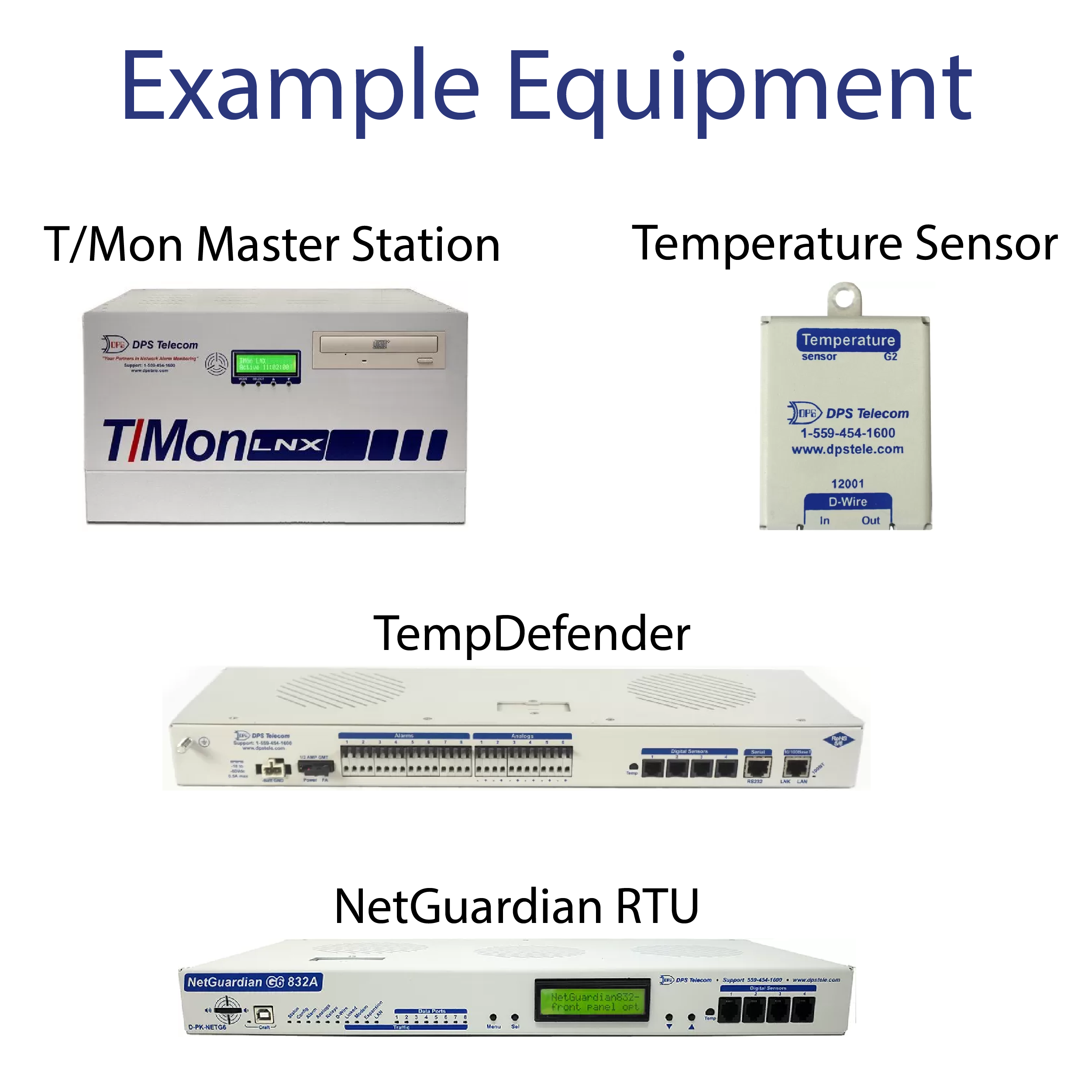

For this kind of monitoring, all you need is one or more temp sticks (temperature sensors) and an RTU (Remote Terminal Unit, or Remote Telemetry Unit) to send the temperature sensor alarms back to you. If you have a medium or large network, you can use an alarm master station to send alerts by text, email, or any other method.

Electronic equipment naturally creates large amounts of heat. If this heat is not monitored adequately with temperature sensors, thermal shutdowns will happen sooner or later.

Deploying temperature sensors to create a temperature monitoring system at your sites will help you dodge service downtime and damage to your gear. These sensors are relatively cheap, simple, and quite compact.

Imagine the situation: your HVAC system stopped working and you didn't have any temperature/humidity sensors at your remote sites for temperature and humidity monitoring. You had absolutely no idea that the temperature was rising until it was too little too late. Both your customers and bosses won't be happy with equipment damage and/or emergency shutdowns, right?

I can't say enough how vital it is to monitor the temperature at your remote sites if you want to avoid having your electronic equipment cooked by excessive heat - or frozen by excessive cold. Temperature sensors should cut your costs and protect your revenue by alerting you at the first sign of trouble at your site.

That's a very valid question when you start planning your indoor temperature monitoring system. In general, there are two types of sensors to choose from:

Digital sensor

Digital temperature monitoring systems will only tell you if the temperature is above or below a predetermined value. The major drawback of this sensor is that you won't be able to know how much the temperature has risen or fallen beyond the temperature threshold you specify. This means that if your alarm threshold was set to 85 degrees F, the sensor might indicate that the temperature was above your set limit, but it won't indicate if it's 86 F or 186 F.

Analog sensor

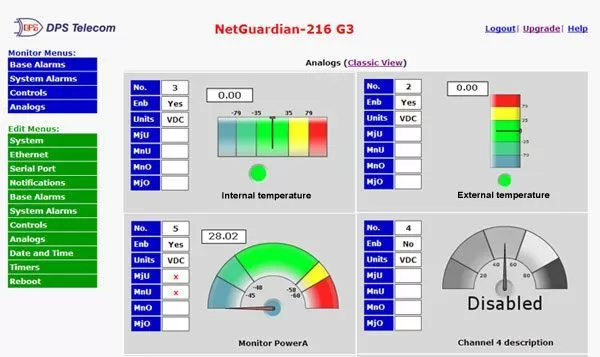

Analog sensors are superior to digital sensors because they measure the actual temperature at your site in near real-time. Instead of knowing that your temperature was just "too high" or "too low," you would know that the temperature was, for example, 96 degrees F. You can also use your analog values to send alarms based on user-configurable thresholds.

Analog sensors are the best option when setting up remote monitoring systems because they provide more visibility. However, if you don't need all the features of the analog sensor, a digital sensor is more useful than not having any type of visibility.

One of the often-overlooked - until the install goes wrong - point when designing a temperature monitoring system is knowing how you'll power your sensors. Don't fall into the trap of thinking that running an expensive external power transformer (also an additional point of failure) is the only way to power your sensor.

To avoid the headache of having a separate power transformer and a power supply for such a small sensor, make sure that you provide direct power to your temperature sensor.

The 2 principal ways that you can do this process are:

Using Direct Single Wire

Direct single wire, also known as D-Wire, is a type of sensor that is powered over the same wire that it uses to communicate with an RTU ("bus-powered:). D-wire sensors also give you the benefit of being "daisy-chainable," so a single RTU input port can accept several sensors through a daisy-chain, and you - with little effort - will be able to effectively monitor temperature at multiple locations within your site.

DPS's line of D-Wire sensors, for example, can easily daisy-chain together to make monitoring your facility easy, giving you complete visibility of every floor. The sensors use simple RJ-11 connectors, in and out, and allow you to chain up to sixteen to thirty-two sensors to a single RTU's D-Wire port. Your sensor chain can be a maximum of 600 feet, so you can run sensors out as far as you need to monitor your equipment, without having to place analog-capable RTUs in multiple places.

Having an RTU with a Built-In +12 VDC Power Supply for External Sensors

Many mainstream analog sensors require +12 VDC to power. In a telecommunication environment, equipment is typically powered with -48 VDC. You could power your sensor via commercial power, but during power outages you'll lose your temperature sensor.

A good industrial practice is to use an alarm remote that will provide power to your sensor from a -48V power source.

The NetGuardian 832A is a good example of one of the few remotes in the industry with this type of feature. This large RTU, that supports multiple temperature sensors, constantly converts -48 VDC to +12 VDC to provide reliable power supply for your temperature sensors.

Take a look at a list of DPS RTUs for every application

Temperature alert systems can really vary in quality depending on the choices you make while researching and purchasing equipment.

Getting the best RTU for your unique scenario should be one of your top priorities, in order to have the best visibility of your sites possible.

Here are some considerations to keep in mind:

Having an effective network means that all your devices can talk between themselves, and ultimately, can pass any information to you. Make sure your RTU is able to "speak many languages," so it can collect alarms and sensors from all the devices you already have at your remote sites, including legacy gear. The multi-protocol feature is your way to go about it.

Using a web browser is a simple task that virtually anybody can do. Choose an RTU that has an easy-to-use, intuitive web interface to make sure all your field techs can access your remote monitoring system, from any computer at any location.

Your RTU should translate your analog sensor communication (simple voltage/current) or your digital sensor communication (discrete contact closures) into alerts that you or your techs can read.

Efficient RTUs will send you email temperature alerts or send text messages to your phone on any day at any time. If you have a master station, your RTU might send a protocol-based alert (usually an open protocol like SNMP is best) directly to it.

If you have analog sensors, you can specify several temperature thresholds that will trigger an alert message when they're crossed. The best alarm remotes will give you minor and major, over and under thresholds. An intelligent remote can provide dual functions: you'll get the continuous reporting of an analog sensor, as well as the alert thresholds of a digital sensor.

You, then, will be able to dispatch the right people to the right place to assess and fix the problem.

Having an alarm remote that sends you notifications is awesome, but having it filter the nuisance alarms is even better. Your techs might stop taking alarms seriously if they're bombarded with status alerts, oscillation conditions, and overall unimportant notifications.

Another point to keep in mind is picking a remote that supports historical storage of temperature values.

The TempDefender, for example, can give you a graph of temperature readings over time. This compact alarm remote, designed for server rooms and data centers, can actually act as a master station as well. It includes a web interface that'll display graphs and charts of temperatures over the course of its monitoring history.

You can access this information using any computer on your network, using any browser, by simply entering the unit's IP address into the address bar. The web interface will feature a username and password login to prevent unauthorized users from seeing your data.

Charts of temperature readings over time provide you with an insight into issues you may not even have noticed before. Some problems, such as unseasonable warm temperatures, and large swings from the hottest part of the day to the coolest, can be detected earlier. That's a big advantage of having superior network visibility: graphs of temperature levels can display recurring cycles or steadily increasing threats. Then, you'll be able to respond accordingly.

Choose an RTU box that has the right sensor capacity that you need. If you just need to monitor one or two sensors, there's no point in buying an RTU with a ton of sensor inputs. The opposite is worse, though.

It's one thing to have more capacity than what you need, but purchasing a unit with too few sensors would be even worse. That's a recipe for inadequate monitoring. Keep in mind that every hole in your temperature monitoring system is another potential threat of network failure that you're not protected against.

Your RTU will be your temperature monitoring device, so it needs to support extreme weather. It sounds obvious, but you'd be surprised by how many untested products there are in the market.

Look for vendors that do perform the Temperature Chamber Test. This test subjects boards to both extremes of the temperature spectrum, from -100 C to 100 C, punishing your device to the point of failure. When exposed to the low end and high end of its suggested operating temperature range, the unit is held there for 30 minutes. While the boards are in the chamber they are put through a wide range of programmed sequences and cycles.

Each unit should be cycled 8 times to not only show that it can operate in those temperatures, but also that it can withstand the constant change. By stressing both environmental factors and load conditions the vendor is able to fine-tune the products operating parameters.

Manufactures that test their devices are able to design products that work reliably and consistently in the most geo-diverse parts of the planet and in situations where your climate control fails or becomes impaired.

No monitoring system is complete without a sturdy design. The last piece of gear to fail should be your monitoring equipment, so don't leave yourself vulnerable with a poorly built system. Don't choose anything less than industrial-grade hardware that's built to last.

This is a short list of some basic functions to help you start planning your temperature monitoring system. If you want a monitoring system that meets and exceeds all your requirements, make sure to discuss customization options with your vendor.

If you have a number of sites and are monitoring temperature - along with other things - at multiple locations, you'll need a master station to pool and manage monitoring all your sensors and alarms.

Getting notifications from an RTU is super helpful. However, during a real emergency, you don't want to waste time trying to remember which of your sites the alert came from, the site's location, set point for your air conditioning, and other factors that will make you understand the alarm situation better.

Avoid leaving room for error. Your master station, polling your sites and sending alerts, can give you access to more specific information about your sites and offer a single point of contact, making things easier for you and your team.

An excellent example of an efficient master is the T/Mon. It can send escalating temperature alerts, and it allows you to configure multiple notification methods for a site and have them sent in a specific order.

If the first notified person doesn't respond to the alert and acknowledge the alarm within a period of time you define, the alert goes out to the next technician. This way, if you do get a temperature alert at your site, you can create a chain of command and make sure that someone finds out about it.

Also, like RTUs, look for master stations that have an accessible web interface that allow you to view your temperature readings and set controls to operate equipment around your sites. Using the example of the T/Mon once again, it offers a graphical user interface called GFX.

GFX is a map-based system that shows you where alarms occur by geographical location. This interface allows you to get a closer look at your sites, all the way down to the floor-plan and equipment views. This is an extremely helpful feature that lets you and your techs pinpoint the problem when you receive an alert.

Independent of which master station you choose, keep in mind that the idea is not simply to receive an email alert when the temperature at your site reaches a critical level, but to be able to identify the issue and fix it, so you can save your vital - and expensive - gear from damage and keep your network up and running.

Combining temperature sensors with competent RTUs and master stations that provide progressive notifications and simple interfaces can help you watch over your sites better, decrease the cost of maintenance, and increase network lifetime.

Along with providing power to your temperature sensors, having a secondary power supply to your HVAC system is also often overlooked.

Having a secondary power supply is important because during power outages your equipment will be able to continue running. If your air conditioning is connected only to commercial power, it will be offline.

Picture this: you've got a perfect-fit solution in terms of temperature sensors and you're ready to go. However, in case of an alert you're not able to intervene quickly enough, simply because there are no techs near the determined site. If you don't have a backup power supply to your HVAC system, the temperature will keep rising - while your gear is still running on backup power - until a thermal shutdown happens.

When you have a secondary power supply to your HVAC system, it can control situations before a forced thermal shutdown happens. Your site won't go dark and your customers will still be happy.

Monitoring your equipment is a serious task - monitoring the temperature and humidity levels that affects your vital gear at your remote sites is no less than a serious task either.

Now that you know how critical it is to not leave your network vulnerable, it is time to start looking for a high-quality temperature monitoring solution.

You already took the first step - and one of the most important - in making the right choice. You're gathering information on what temperature monitoring is, and the basic aspects to achieve a perfect solution.

After you've armed yourself with all this information, you can start your search for the best vendor for you. Knowing the principal aspects of what you're trying to buy is really important, because then you won't have to just accept your seller's words for everything.

If you're interested in a personalized solution for your unique scenario, you can contact me. I can answer any questions that you might have, as well as help you design the perfect-fit monitoring system for your network.

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...