Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayAn Uninterruptible Power Supply (UPS) is a backup power source that activates when the main source of power fails. Although complex, a UPS has a very simple overall design. Every UPS has power inputs (for the intake of commercial power during normal operation), power outputs (to connect protected equipment), and backup batteries (to prevent interruption of power to protected gear when commercial power is lost). It also has a control system that quickly switches to backup battery power when the main source of electricity goes down.

The word "uninterruptible" means that the power supply will act quickly enough to prevent the gear from ever losing power when the main power source goes dark. This usually means that a UPS system must be capable of activating backup power within 25ms of a power loss.

A UPS is, by nature, redundant. This means that it provides an important protective barrier against data loss, outages, and expensive hardware damage (by smoothing out voltage anomalies).

In consumer applications, a UPS may only have enough battery reserve to last for a few minutes. The intent of such a short backup power supply is only to allow the safe shutdown of connected computer gear.

In a telecom or data center environment, however, the batteries of a UPS may last for several hours or more. If commercial power failures are most likely expected to be rare and brief, a UPS may be the only backup power source at a remote site. However, at least one diesel or propane generator can also be present to provide backup power.

Whatever your particular scenario is, if you depend on a UPS system to protect critical gear at your remote sites, then you want to remotely keep an eye on it. Let's explore some more facts about the UPS, and the most important techniques and key factors that you should keep in mind to achieve a successful UPS monitoring system.

As I said previously, an uninterruptible power supply is vital protection against loss of data and costly hardware damage.

Unfortunately, though, many network managers fail to properly monitor their UPS systems. The main cause for this is that most modern UPS systems for use in industrial applications include a built-in web interface for ups critical tracking. Although this obviously allows "monitoring," one critical failure prevents it from being "proper monitoring."

Using an uninterruptible power supply's own interface for performance and up-time defeats the purpose of such monitoring. What happens if the UPS fails? Well, so too will the monitoring interface that you have relied on.

Instead, the industry's best practice is to deploy UPS power management software. These can come in small monitoring devices (1 RU or less) that are available to collect important status information from virtually any UPS backup system.

These monitoring devices are called "RTUs" - short for Remote Terminal Units or Remote Telemetry Units - and they'll send alerts back to critical personnel via LAN, phone voice message, serial connection, T1, fiber, or any other available transport.

Take a look at the DPS RTU devices here.

This way, companies will have remote access to their UPS systems and can track and log the voltage levels of each single battery cell, providing a good assessment of the overall health of the battery string. Even better, RTUs will monitor much more than just your UPS system. Just about every piece of telecom, transport, and switching gear you have will also benefit from external monitoring.

A good RTU will contain its own internal UPS with backup batteries large enough to continue operation for at least several hours after a power failure. Some of the top-quality RTUs will last for up to 10 hours.

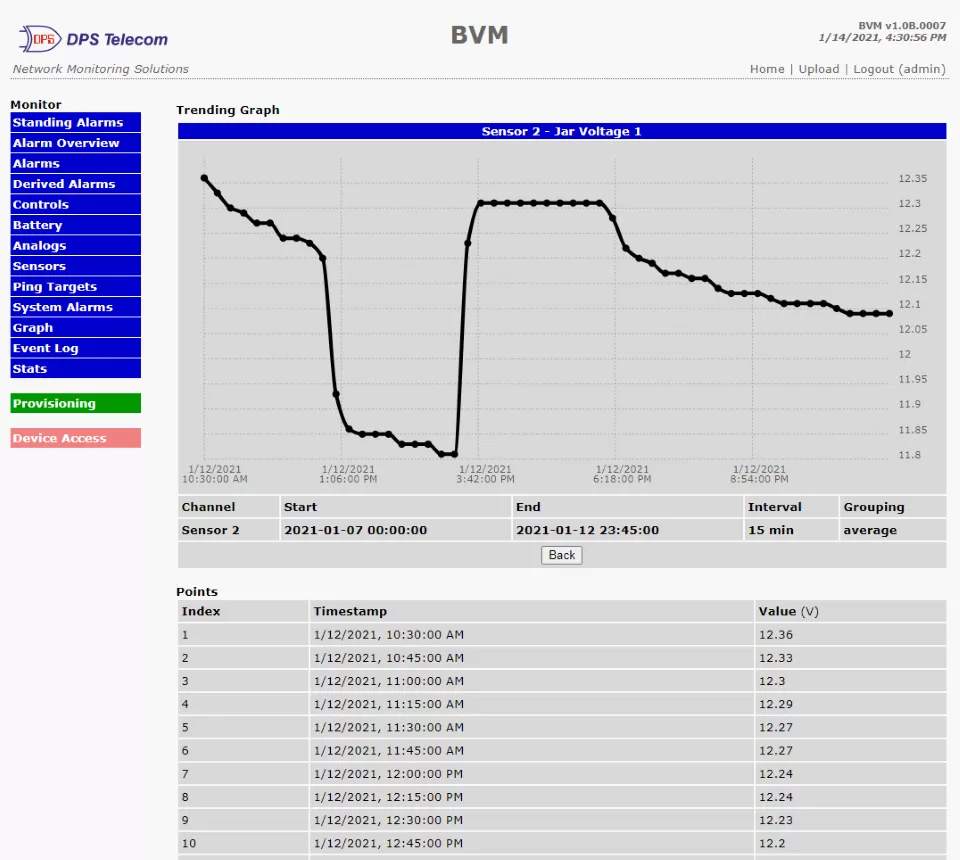

Your battery monitoring system needs to provide you with continuous voltage readings. Without regular monitoring or at least control over the sampling rate, a problem can linger for too long before you're notified. That's why sampling your batteries at too long of intervals can be so problematic.

Your battery cells can easily become fully discharged between lengthy interval readings, which means you risk losing power at your sites and won't have any idea until the entire site suddenly goes dark. With real-time monitoring and customized interval samples, you can be assured you'll know about these kinds of emergencies before they bring down your vital network gear.

I've seen many clients roll out uninterruptible power supply monitoring systems at dozens of sites to protect the battery cells there from expensive damage. The battery monitoring systems that they deploy cover both VRLA (Valve-Regulated Lead-Acid) batteries and flooded batteries. Overcharging, at a level of 20 amps per 100 amps of battery capacity, is monitored carefully.

Monitoring voltage to prevent deep discharge is perhaps the most important role of the uninterruptible power source battery monitoring solution. As an example, if you discharge batteries at 48V and they drop to 42V, you have probably damaged the batteries.

You also want your battery monitor to have the ability to work with different battery types and voltages. All batteries are not the same. They have different orientations, connectors, and different voltage ranges - for instance, you might have a standard string of batteries or a string with four 12V cells and propriety connectors. You need a battery monitoring system that is very adaptable.

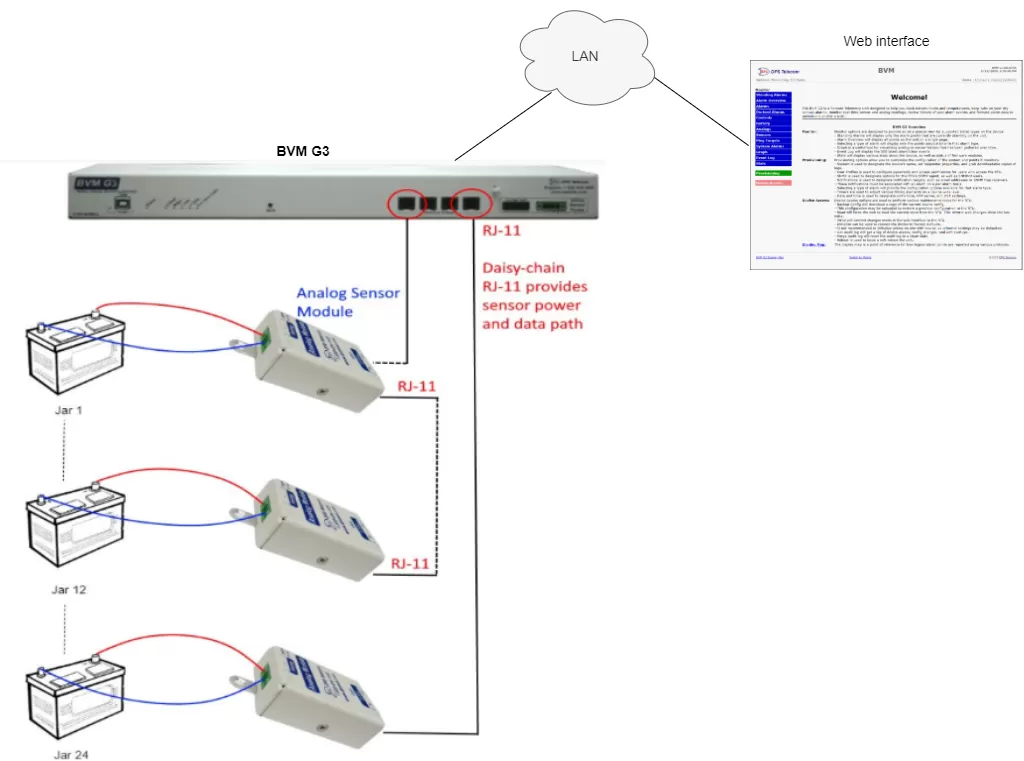

This is why the DPS BVM (Battery Voltage Monitor) integrates directly with NetGuardian RTUs: to provide real-time, continuous voltage sampling rather than just periodic snapshots.

Some battery voltage monitoring systems don't support the capacity to handle your large quantities of battery cells. It's absolutely key that you have the full support to monitor each of your battery cells. Otherwise, you'll find yourself vulnerable to the weakest link of the battery string.

Most of your vital sites will have A/B power battery systems. Look for a robust RTU, like the NetGuardian 832A, which is engineered to monitor both A/B strings simultaneously. Not all strings are created equal - so make sure your monitoring solution can monitor up to a 125 VDC string.

Tracking and logging the voltage levels of each single battery cell provides you a good assessment of the overall health of the battery string.

How important are your batteries to your network? With your up-time depending on your batteries, it's simply too risky to leave such a vital aspect of your network unmonitored. All it takes is a single bad jar or fully discharged battery and your entire network can come to a screeching stop. You need to be confident that your power system will remain running because you aren't there to monitor it.

Since a single bad battery jar can degrade the performance and lifespan of an entire array of batteries, it's critical you deploy a superior battery monitoring system. Monitoring the entire string is better than no monitoring at all - but it's not the most effective way to improve reliability. String voltage doesn't tell you how many cells have degraded and to what extent.

While some monitoring is better than no monitoring, having a good monitoring system will save you a lot of trouble in the future. Most systems have one sensor for the entire string of batteries. It may alert you that there is a problem. However, this system has no way of knowing which battery is causing the problem.

And that's the best-case scenario. In most cases, one battery will go bad, but the others on the string will pick up the slack. This puts a strain on the remaining batteries, but you're never notified because the sensor reads that everything is in working order.

A good battery monitor will have sensors to monitor each of your cells individually - looking not just for low voltages - but a difference between the cells and the average of all the cells. A system like this will not only save you network downtime but will also preserve the lifespan of your batteries.

Since your UPS system is the first line of defense when commercial power fails, it's critical that you know how much power you have remaining. You can tie the string output voltage to the RTU for monitoring, and your RTU will extrapolate "battery life remaining" from that voltage measurement.

In fact, some of the better RTUs will have their power inputs internally tied to an analog circuit. This reduces your wiring requirements, as the very same wires that are supplying battery-plant power to your RTU are also being monitored for voltage.

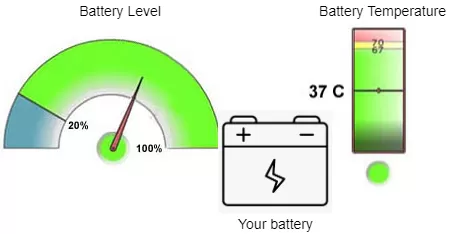

Battery temperature is also a good general measure of battery string health. A temperature that rises too high is a strong indicator that something may be wrong.

There are some very granular battery-monitoring systems available that tie a sensor pod to every cell in your battery string. But these tend to be quite expensive - to the point where many people say "I could replace my entire battery string for less than what that monitoring system costs."

A pair of analog inputs (one for each voltage and temperature) is a good monitoring technique that you can install at a relatively small cost.

There are some very complex ways to measure your batteries (sensor node on every cell, capacitance, internal resistance, etc.), but the simplest and easiest way to start is to track voltage to monitor battery life remaining, plus temperature to detect overheating before damage occurs.

It doesn't matter the size of your company, a flexible range of notification options gives you effective reporting methods.

When you go with DPS products, battery threshold alarms can be reported in the following ways:

When it comes to monitoring your batteries - and therefore protecting your up-time - you want true flexibility. Having the capability to receive 24/7 alerts (via text message, email, voice alerts, etc.) about the status of your batteries can be the difference between a power outage and keeping power to your gear.

Even if you have a 24/7 dedicated NOC (Network Operations Center), receiving on-the-fly and mobile alerts from your battery monitoring system can give you an edge in avoiding preventable outages. If you do not have an uninterruptible power supply with email notification, Look for a battery monitor that can alert you via emails, text messages, paging, etc. With notifications that can reach you even when you're out of the office, you can be assured you won't be left in the dark.

Learn more about battery monitoring with our white paper - Monitor Your Battery Cells for Superior Reliability. Download it here.

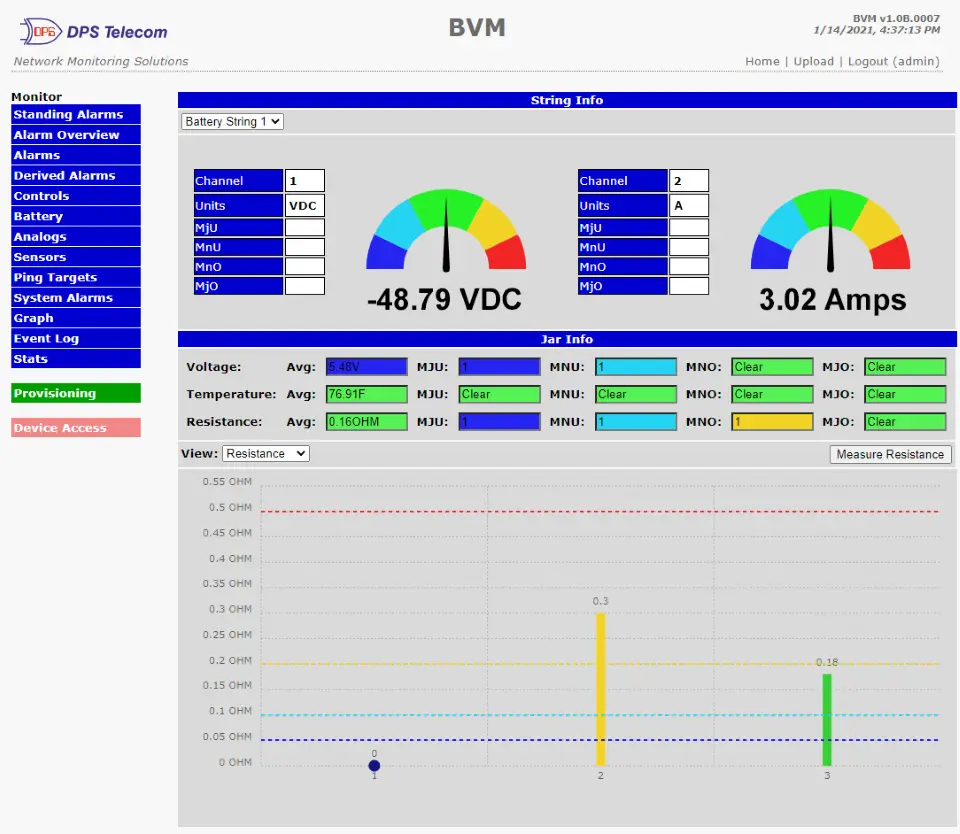

When looking for UPS monitoring systems, make sure to get a device with a web browser interface that will present you with powerful remote control and monitoring tools. Instead of driving all the way out to your site to configure or manage your device, you'll be able to do it right from your desk. This can save money on fuel costs and expensive man-hours.

Your company might be large, you might also have an enterprise-grade SNMP manager, but a web interface lets you drill down when you need to. An intuitive and easy-to-use web interface is way above any other method to manage your battery monitoring.

Do you know the status of your remote site battery strings? Would you know if one single cell was falling out of its ideal voltage or temperature range? At many companies, battery cell monitoring is a commonly overlooked opportunity to reduce costs and improve reliability.

This actually creates a huge problem. If you've ever had battery failures in the past, you know just how painful they can be. A single bad cell can greatly affect an entire string of batteries if you don't catch it early. An entire site can go dark if your batteries aren't working properly or become fully discharged.

Remote battery alarm monitoring and control isn't always as simple as slapping a single voltage monitor on each string. To really know the big picture, you need a high level of detail.

Fortunately, you can always count on the BVM G3. It integrates battery sensing into remote alarm monitoring. This creates a single unit that gives you the capability to monitor alarms from your equipment, environmental conditions, and battery strings.

Here are the main features of the battery monitoring system itself:

This battery monitoring solution gives you complete visibility over battery conductance, voltage, temperature, and resistance. These proven key indicators will give you advance warning of deteriorating battery cells. This means you can avoid being blindsided by a faulty or fully drained string.

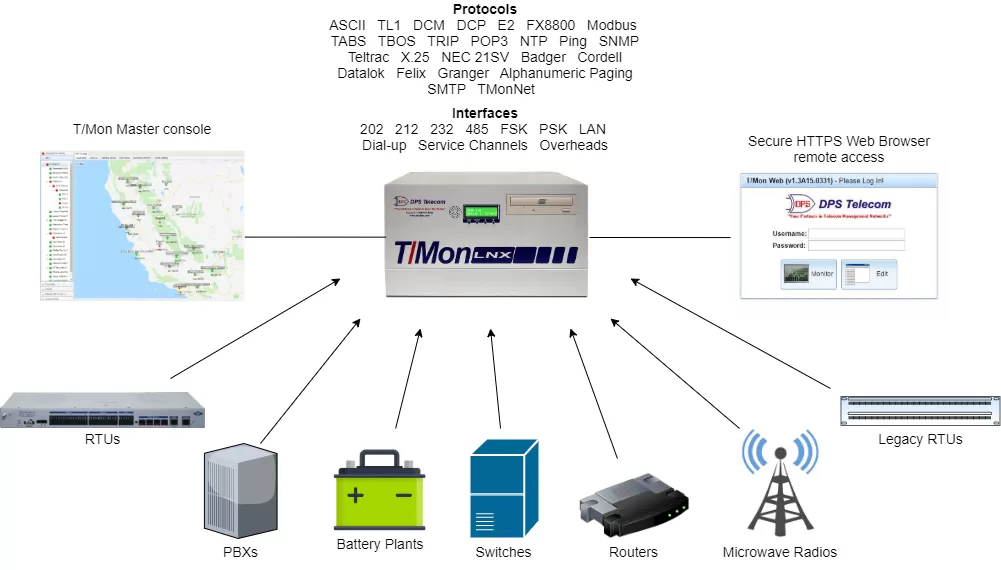

If you need more than a handful of RTUs, it's important to deploy an efficient master station. The T/Mon LNX is the best option if you want a cost-effective monitoring solution.

Monitoring UPS systems is an important part of any truly reliable network. You simply can't afford to leave your battery strings vulnerable. While some monitoring is better than no monitoring, the right monitoring system makes all the difference. If you want to get more information about how to monitor your UPS system, or want to speak with me or someone on my team about designing a monitoring solution for your network, please contact us today.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.