Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayThe equipment in server rooms use more power and makes more heat than ever before. High temperatures can cause gear to work poorly or even cause damages. Internal pieces swell and pull away from each other or can simply burn. Efficient server room temperature monitoring and maintenance is critical in to keep your gear safe and performing at 100%.

HVAC and CRAC units are expected to maintain a controlled temperature between roughly 61 and 75 F. Chances are you won't want the room temp to spend much time on the upper end of that range. It's also likely that the equipment in the room will generate more heat and require more cooling power.

In order to avoid problems that affect your revenue, it's important to know how you can monitor temperature. So, let's talk about some ways you can do that effectively.

Not only you can't simply let your servers run at high temperatures for fear of damage. Nor can you let your server rom suffer high or low humidity, which can short your equipment. While this sounds easy enough, as equipment pushes 750 watts per square foot, it isn't enough to simply crank up the air condition and expect your server room to stay cool.

The air in your server room, especially nearest the processors in your equipment, will rise to dangerous temperatures quickly if not properly cooled and circulated.

You don't want your servers and rack-mounted equipment taking in the hot air exhausted from other servers, otherwise you'll start seeing equipment failure, or, at the very least, inefficient server activity.

Even if you had enough air conditioning units that could keep your server room at a reasonable temperature, you would expend a costly amount of energy doing so. There are more efficient ways to keep your server room cool.

You know it's important to keep your server room and equipment cool, but do you really understand why?

Extreme heat and high humidity can cause major damage to mission-critical gear. In the case of high-heat, many of the components in your equipment are only rated to operate within a specific temperature range. If your server room temperature exceeds that limit, pieces of your equipment can stop working - or even worse, fry completely, making them permanently damaged.

For humidity, it's a known fact that water and electronic equipment don't mix very well.

Your gear can handle a small amount of water that's naturally in the air. However, if the humidity hits a certain percentage, you might start experiencing some trouble. If the humidity levels in your server room get too high, the water in the air can actually cause your equipment to have electrical shorts.

While you may get lucky just drying it out, most of the time the water damage leaves the equipment permanently damaged and it'll need to be replaced. To save yourself from having to replace expensive gear due to preventable damage, make sure your server room is appropriately monitored.

Server room cooling relies on a number of different variables. These include:

Air flow

Humidity

Return

Equipment distribution

That's why you'll need to monitor the effectiveness of your server room's environmental systems in many places. You must ensure that the system is working properly. You can't simply leave environmental monitoring to the environmental controls in the server room, as they're placed only at areas where cooling, air flow, and humidity are most easily controlled.

Just because everything is fine with your CRAC units, it doesn't necessarily mean that the cold air is being distributed to the right spots in your server room. Humidity may be fine in your return-air space, but on the server room floor - at a different temperature - you may measure something different.

The varied environment of the server room demands that you spread sensors and monitoring equipment throughout your server room.

Liquid-cooled systems can help cool things down.

These kinds of systems run chilled water or liquid coolant through coils near, on, or through your servers and racks to keep them cool. Liquid cooled systems are often rack-mounted closed-systems that refrigerate and recycle coolant as it passes over, under, and around your hot equipment. Keep in mind that, of course, liquid chilling is pricey and adds bulk to your server room.

If yo're looking for the best ways you can keep an eye at your server rooms, the following points are the best strategies you can adopt.

If temperature, air flow, and humidity are all within proper ranges in the most extreme spots in your server room, you can rest assure that your cooling systems and equipment distribution are working out.

If environmental levels are within normal ranges at the server level, inside the racks, then, obviously, your HVAC equipment is working fine.

This is the most expensive route, but the most thorough and most recommended to ensure the safety of your equipment.

Of course, no matter what strategy you choose, you're going to need to guarantee that your server room maintains a cool temperature either way. You can't afford to wait until a server melts to find out that a part of your server room's temperature management system has failed.

It's expensive both in the cost of gear and potentially the number of clients you may lose due to a service-affecting outage. So, you'll need a proactive monitoring system to keep you informed about what's going on within your server room, this way you can take action before a major failure occurs.

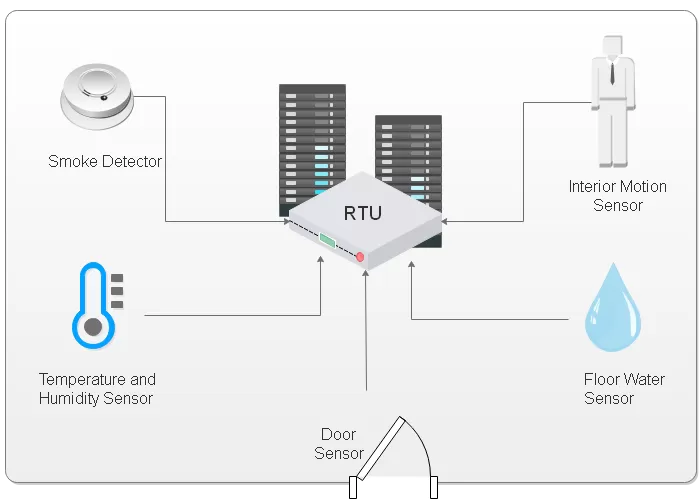

Therefore, in order to put those monitoring strategies in practice, you need good RTUs that can give you the best visibility possible.

Here's two example of efficient RTUs that can help you better monitor your server room.

With the TempDefender you can monitor multiple spots in the server room from a single device. It's a small, rack mountable RTU that can handle up to 16 analog sensors reporting on all of the environmental factors in your server room.

Sensors for the TempDefender may be daisy chained together, so you don't have to run a mess of cabling back to the remote. You can also string sensors up to 600 feet away from the RTU, allowing you to run sensors to the most extreme spots in your server room from a centrally located device without worrying about connectivity issues.

Be careful if you measure your server room cooling system this way. Be sure to run sensors to spots likely to be hot. These include: above equipment, hot isles, and near your hottest racks. You should also place sensors where air flow is most necessary. This can include hot air aisles on both sides of your cold aisles. This will ensure even cold-air distribution.

You want to ensure that air, both cold and hot, is being effectively moved through the system. Losses and inefficiencies result in hotter server rooms and more energy expended in the cooling process - it's not as bad as a complete meltdown, but still not optimal.

If you would prefer a rack-to-rack solution, you should consider something like the NetGuardian 216 remote. This unit has four analog inputs, with which you can measure the environment within the rack (or string sensors across a few racks) and 16 discrete alarm inputs, so you can directly monitor your servers and other equipment.

The NetGuardian 216 provides a total solution that allows you to monitor environmental sensors and the dry contacts coming directly from your servers, so whether your problem is environmental or otherwise, you'll know about it.

Installing RTUs on every rack is the pricier solution. Although it provides direct monitoring for your servers, which will help you ensure their safety and continued function, it doesn't necessarily tell you much about cooling systems in your server room beyond whether or not they're adequate.

Measuring individual servers and racks will not likely clue you in to inefficiencies in the system.

It's also important to have sensors that operate seamlessly with your RTU to give you complete environmental visibility of your server room. Sensors allow you to monitor your server room conditions instantaneously, so that you can fix a problem before it gets worse.

The D-Wire sensors feature temperature, humidity, and air flow measuring capabilities and up to 16 sensors can be daisy chained together. Other sensor options include temperature sensor with a probe, non-D-Wire analog temperature and humidity sensors, smoke detectors, and exterior weather sensors.

Server room cooling is a never-ending battle. As technology continues to observe Moore's law, and both processing power and energy draw per square foot increase, it gets warmer and finds new ways to confound your server room's environmental systems.

However, when you combine your chosen monitoring strategy, with the TempDefender - or the NetGuardian - and sensors, you'll get the most complete view of the state of your server room.

It may seem like a large investment, but think about it as an insurance: you can't afford to leave your equipment vulnerable to damage.

So, give us a call. I and my team will be happy to help you plan a perfect-fit monitoring solution for your server room.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.