Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayFirst of all, what is SCADA and PLC? A SCADA (Supervisory Control and Data Acquisition) system is a type of distributed control system that consists of a central station and remote sensors. The central station relies on the sensors to gather and report telemetry data. These sensors can be Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs). The RTU or PLC collects information locally and then passes it on to the central station in real time. Once the central station has the remote information it can send out notifications, generate alarms, or initiate automated responses.

RTUs and PLCs today are capable of controlling the actions within their range of vision through closed loop feedback systems. The central station oversees the overall performance of the one or more RTUs/ PLCs under its control. SCADA systems also allow staff or supervisors to change the settings as appropriate at the level of the RTU/PLC or the central station. Alarming conditions like high temperature can then be stored and displayed.

So how would SCADA interface with PLC or RTU? Let's review Remote Telemetry Units (RTUs) and the sometimes less expensive alternative, Programmable Logic Controllers (PLCs). Both devices collect data and send it back to a central master. While their primary purpose might be the same, there are differences with respect to their design, installation, and operation.

Capacity

A PLC usually has relatively limited input/output capabilities. In most cases this is nothing more than a couple of digital/analog inputs, a similar number of open-collector/relay outputs and sometimes a single interface shared for configuration. A RTU has more capacity with 30+ inputs, several outputs and a lot of communication interfaces.

Ease of Use

Interfacing PLC with SCADA brings its own set of challenges. It is not uncommon for a PLC based SCADA systems to require external programming or script writing in order to perform its monitoring role. While this can often be done with an included GUI application, the point is it must still be done. More than likely by someone with a lot of programming knowledge. If you are planning a PLC based SCADA system, you should expect to spend a considerable amount of time configuring your units.

RTUs, on the other hand, come pre-set for deployment into a SCADA system. A RTU will often include an embedded configuration web application that requires nothing more than a standard browser connection for setup. A RTU can also be accessed for configuration even while it is actively monitoring.

Space Requirements

Just because an RTU has a lot of capability compared with a PLC, that doesn't mean you'll need acres of space to install one. In fact, many medium SCADA RTUs are only one rack unit (1.75" or 4.4cm) tall, and less than a full rack width across (commonly about 10" or 25cm). If you don't have rack space nearby, ask the manufacturer about wall-mounting ears that will allow you to mount the RTU on any flat surface or wall.

Purpose and Functionality:

An RTU is designed specifically for remote monitoring and control. It collects data from various field sensors and devices, transmitting that data back to a central SCADA system. It excels in harsh, remote environments due to its robust design and compatibility with multiple communication protocols like SNMP, DNP3, and Modbus. A PLC, on the other hand, is optimized for real-time process automation. It manages complex control tasks like machinery operation and is commonly used in industrial environments like factories.Environment and Deployment:

RTUs are often found in remote, outdoor, or utility-based environments such as telecom towers, power substations, and water treatment facilities. They handle environmental monitoring, alarm reporting, and even power management using integrated sensors and control relays. PLCs are typically installed in controlled industrial settings, operating machinery, production lines, or automated systems within manufacturing plants.Communication and Integration:

RTUs are integral to SCADA systems, designed to operate over long distances using a variety of communication methods, including satellite and cellular networks. They provide seamless integration with SCADA platforms like T/Mon, offering comprehensive alarm management and remote control capabilities. PLCs usually communicate within local area networks (LANs) and focus on closed-loop control systems in process automation.Data Transfer Speed and Timing:

The speed at which data is communicated varies significantly. PLCs are known for their rapid communication between field devices, systems, and themselves. This is primarily because PLCs transfer data at regular intervals, ensuring a constant flow of information. On the other hand, RTUs function differently. They focus on transferring only the requested data, which means their data transfer processes are driven by specific events rather than routine intervals. This event-driven nature allows RTUs to efficiently manage and prioritize data based on immediate necessity.

Focus on Components:

When considering the interaction with ancillary devices and systems, RTUs are selective. They specifically handle the data pertinent to the events that trigger them, which can be advantageous in scenarios where bandwidth conservation is critical.

In summary, while both RTUs and PLCs serve critical roles in automation and control, RTUs are best suited for remote monitoring and long-distance data communication, making them essential for SCADA RTU systems in utility and telecommunications networks. PLCs, in contrast, are tailored for real-time control in manufacturing and industrial automation.

Choosing a PLC or RTU

When it comes to your SCADA system, you want something that is reliable and is going to have all the capabilities and functions you need. An RTU is the superior choice because they are more robust and better suited to the high demands of a SCADA system. However you should be cautious, some PLC units from major manufacturers are marketed as RTUs largely because of their input/output capabilities. However, they have the same awkward external programming required in order to perform basic monitoring and control functions. Be sure you know what you are purchasing and that the system covers all of your needs.

Industry-Specific Considerations

Choosing between a PLC and an RTU often hinges on the specific industry application. Each industry tends to follow common procedures and standardizations, which can influence which device is more appropriate. For instance, industries with stringent environmental conditions might favor the robustness of an RTU, while those with complex automation requirements could lean towards a PLC for its flexibility.

Both devices excel in different applications, and understanding the operational demands of your industry is crucial. Consider factors such as:

Why Choose RTUs Over PLCs?

Here are a few things to look for in a good SCADA RTU:

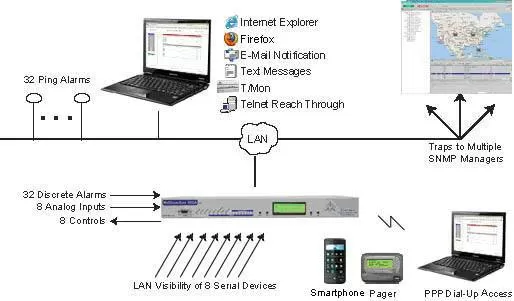

With its many inputs, an RTU in SCADA contexts will use its LAN or serial data reporting channel(s) to send alarms to your central console or HMI (Human-Machine Interface). This makes the single RTU's data part of your management system. If you or your HMI determine that a change must be made to keep your process running smoothly, you can send a command through your HMI and back to your RTU. The command will then be done by the control relay outputs. Just about any piece of gear, button, or switch can be manipulated by wiring it into a standard control relay output.

Don't compromise when it comes to your SCADA system. Get an RTU that is reliable and suited to your specific needs.

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.