Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWeather fluctuations can make humidity levels highly unpredictable, so monitoring the humidity of your facilities is necessary for maintaining network stability and preventing failures.

In warmer temperatures, humidity typically increases as the air is able to hold more moisture. The excess moisture can permeate into hardware systems and in certain conditions condense. This can short-circuit expensive electronic components or - at least - create spurious unexpected connections.

On the other hand, low humidity can dry-out seals and other protective elements. It can also increase the chances of static electricity discharge with possible catastrophic effects on sensitive electronic circuits.

These issues can lead to substantial repair or replacement costs if humidity is not monitored and controlled. Alternatively, problems can be reduced or eliminated by careful remote monitoring and control using humidity sensors.

A humidity sensor is a device used for providing ongoing measurements of the air's relative humidity. This works by running an electrical current between two nodes and then monitoring the amount of voltage created by the air's moisture.

Humidity sensors are a type of telemetry sensors. They are important to remote monitor and control humidity levels and to ensure the safety of your electronic infrastructure.

Purchasing a quality humidity sensor will quickly improve the safety of your network. Depending on the needs of your business, humidity sensors come in a lot of different shapes and sizes - sensors can be large or small, internal or external, and stand-alone or daisy-chained. Some sensors have external probes for reaching specific locations, where others are contained inside small boxes for ambient monitoring.

When selecting a humidity sensor, be sure to look for sensors that can adapt to your environment and provide you with reliable and easy ways to monitor your infrastructure.

Humidity sensors are the easiest solution for preventing humidity damage. They can automatically monitor your equipment, allowing you to focus on the important areas of your operations. Ultimately these sensors provide peace of mind - monitoring your network's equipment and ensuring the quality of your overall network.

Humidity sensors report moisture levels in two different ways: digital (also called discrete) or analog.

Discrete sensors collect digital information in the form of "on" or "off" values. While analog sensors collect live values from environmental conditions. After that, this information is reported to you as a real value, instead of just on/off values.

Digital sensors are able to monitor conditions for operation within a specified range. When the conditions pass outside the monitored range, the sensor closes a contact (sends an alert). When the conditions return inside the monitored range, the sensor opens the contact (meaning that it clears the alert). The signal is reported as a binary (0/1; on/off; open/close; high/low) type of input.

A good use case for sensors would be when your systems are hosted remotely.

For the sake of argument, let's imagine you're hosting your humidity monitoring on a remote island. In addition, you want to keep the humidity a sub 50% threshold so once the humidity reaches 50%, your digital controller will automatically turn on your dehumidifier. If there's a problem, such as extreme heat - and the dehumidifier doesn't completely alleviate the humidity - unfortunately there will be no other option for your equipment.

Analog sensors are more advanced and provide continuous visibility to current conditions. An analog sensor can monitor humidity within a set range, thus providing you with an exact and continuous percentage.

An analog sensor can perform the same functions as a digital sensor, but multiple times and within a single sensor.

Using the previous example, imagine that you were using two analog sensors. Using control relay output on the RTU, your analog humidity sensor would turn on that same dehumidifier at 50%, but could also turn on a second dehumidifier at 60%. In addition, an analog humidity sensor would allow you to view the exact percentage of humidity in your home (for instance 50%, 51%, 52%, etc.).

Digital sensors would only tell you that both rooms are above 50%. Analog sensors allow you to assess the complete situation and respond more efficiently.

If you want the continuous reporting of detailed humidity levels, an analog sensor is the best option for you.

However, if you are considering analog sensors, keep in mind that - although they are generally reliable and get the job done - they definitely have some downsides.

For starters, they must be wired into on-site power to operate. This is fine for one or two sensors, but any more and you will be spending a lot of time wiring.

In addition, they generally require +12 VDC or +24 VDC, which may not be available at your location. In order to supply power to each unit, you need to put a voltage converter between your sensor and your rectifier - thus adding more wiring.

Once you have the analog sensor powered, you need to wire it to your RTU using one of your limited analog inputs. One sensor might be OK, but if you need multiple sensors, your analog inputs will quickly be used, leaving no room to monitor anything else.

When you plug in the sensor, the RTU can sense incoming electrical signals, but will not understand what type of unit it is. In other words, it won't be able to differentiate between a temperature or humidity sensor, nor see whether it is outputting voltage (0-5v) or current (4-20mA).

Additionally, you have to scale the device. Scaling is the process of telling the RTU how to convert the voltage input to a human-readable output.

For example, your analog sensor will come with a preset scale, usually noted on the side of the device. It may state that a value of 0 volts = 5 degrees F and that 4.7 volts = 100 degrees F. If the sensor reports a value of 2.8V, the RTU uses the scale to convert that to 77.4 degrees.

Unfortunately, scaling is necessary with analog sensors. While the method is very accurate, it's still an extra step. It can also be confusing if you haven't set it up before.

While traditional analog sensors are a good option, forward-looking manufacturers are moving towards sensors that require only one wire. These units are a better option for several reasons.

First, they only require one wire to transport both data and power. This lessens the number of wires needed and removes the clunky wall transformer units.

Imagine being able to quickly and effortlessly plug the sensor into your RTU and having it function right away, straight out of the box. You only need a single, common RJ-12 cable to install, no specialized cable, or expensive equipment. Plus, you can easily crimp new RJ-12 cables in the field for quick repairs.

Since these sensors are easy to install, you won't have to spend hours training techs on how to incorporate them into the network. Best of all, they boast the same, if not better, reliability when compared with traditional analog sensor.

You don't have to sacrifice quality for ease of use.

Our line of sensors is called D-Wire. There's a variety of sensor types. They provide easy-to-use, easy-to-install functionality and reliability.

One simple RJ-12 cable connects the D-Wire sensors to your RTU for monitoring of critical environmental levels. To conserve ports in your unit, up to 16 D-Wire sensors (with a maximum of 600 feet) can be daisy-chained through one port. No more using up valuable analogs to monitor each sensor individually.

Provisioning, or editing, the sensors is easy to do as well. Each D-Wire sensor is uniquely identifiable by the RTU. It can sense the unit and distinguish what type of device it is. This means that, if a sensor becomes unplugged, the RTU will detect this and alert the appropriate person.

You can monitor humidity, as well as temperature, using the D-Wire Temperature and Humidity combination sensor. This device can accurately report the live-analog values for temperature (+/- 2 degrees F) and humidity (+/0 4% RH).

No matter which type of sensor you choose, an RTU is the most important part of your humidity monitoring system.

Humidity sensors, which are a fundamental node of your alert topology, are typically monitored continuously by an RTU - short for remote telemetry unit. The RTU takes the input from the analog or digital devices and uses that information to perform advanced monitoring functions. The collected data is processed locally by "intelligent" RTUs for thresholding and notification, forwarded to alarm master systems for similar processing or both.

In other words, the RTU is responsible for notifying other equipment in real-time to respond to changing humidity levels.

If you integrate your analog sensor with an efficient RTU, you can view the monitored value from anywhere in the world. Quality RTUs can process the collected data locally against multiple threshold values and generate a binary signal when a threshold is crossed.

Importantly, the RTU should report not just the generated binary signal but also the monitored analog value to the master station. In larger systems, it's sometimes easier to administer analog thresholding at a centralized master rather than distributed to each remote throughout the system.

The most advanced RTUs even provide email, text, and voice call notifications to alert you of emergency situations.

Because there are so many different types of RTUs out there, choosing the right unit can be difficult.

In my experience, it's best to look for RTUs that will work with your current situation but also provide functionality for your long-term goals. Try to find an RTU that is a perfect mesh of integration, interface, and size.

In addition, watch out for large manufacturers who use cheap plastic cases and fail to individually test each of their products. When selecting an RTU, quality is much more important than quantity. The RTU is the brain of your humidity sensor so it's critical to choose a reliable and efficient one.

No matter which humidity sensor you choose, be sure to consider what is best for your system.

The NetGuardian 832 is a popular choice if you are looking for a medium-sized unit with SNMP protocol and all of the advanced functions. The NetGuardian supports customized alerts (through text, email, voice call, etc.) and provides an integrated web interface (via your web browser) to view your equipment from any location.

In addition, this RTU is a nice option because it's quality tested, created with a durable metal case, and customized to fit the exact requirements of your system.

The bottom line is that the quality of your humidity monitoring system will enhance the overall efficiency of your network. This means that, by choosing the right humidity meter, you will instantly safeguard your network and secure your revenue stream.

With so many different selections available, it can be difficult to choose the right options for your business. Here are several qualities to look at when deciding on the best humidity monitor:

When it comes to managing the status of your systems - and therefore protecting the quality of your network - you need to have up-to-date readings on the condition of your remote sites. Having the ability to easily access this information from any location is necessary for saving you time and money.

Finding a humidity monitor that updates your information within seconds, through several easily-accessible interfaces, is the most efficient way to manage and protect your business.

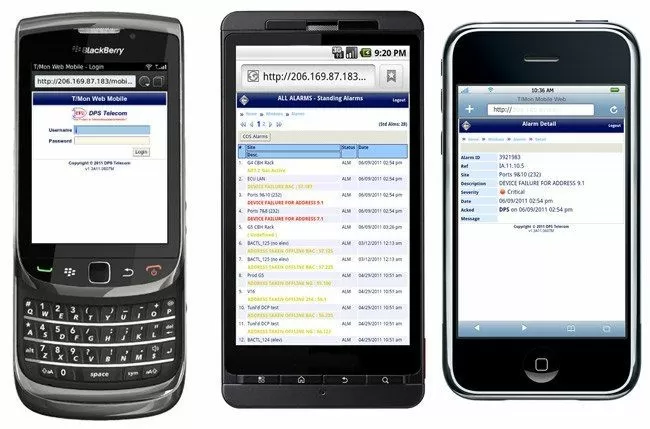

Advanced humidity monitoring systems offer several options for accessing your remote site data. Some systems provide a menu-based interface, operating from software installed directly on your computer. Other systems offer web-browser interfaces that are accessible from any computer with internet access (through an IP address). The most advanced forms of these interfaces provide detailed geographic information, including alarm locations, history, and repair analysis.

Your humidity meters needs to provide you with important updates on the condition of your network. Due to climate, weather, and natural disasters, levels of humidity can rapidly fluctuate and destroy your infrastructure.

With customized alert notifications, you can choose the conditions of your alerts and instantly stay informed on important developments in the status of your systems.

Look for RTUs that provide a wide range of options, including emails, or voice, and text messages sent directly to your cell phone. If humidity levels rapidly rise, a custom alert notification could be the only solution for quickly notifying you of your site's status and helping to save your network devices.

Without adequate sensor coverage, you could incidentally neglect an area of your infrastructure and sustain devastating network losses. The most advanced sensors cover a wide range of temperatures, come in different lengths of probes, and can be chained together to cover all of your site.

Look for humidity sensors that can adapt to your environment and provide complete coverage for all of your hardware.

As I said before, no matter what you choose, whether analog or discrete sensor, a good RTU can make all the difference. If you are unsure on what type of sensor to decide on or plan on using both digital and analog, many RTUs contain ports for both analog and discrete inputs. The NetGuardian 832 has room for 8 analog alarms and 32 discrete alarms with the ability to expand to 176.

The majority of humidity sensors run off of power, with a protected battery plant connected to the RTU and other critical equipment in case of unexpected power failure. But often, these devices fail to integrate the back-up energy support within each individual sensor. When the power fails, all sensors that are connected to the main power supply also stop working.

The most advanced humidity systems connect their individual humidity sensors to emergency battery support via the RTU, ensuring that your sites are constantly covered even in the direst energy situations. Always choose humidity sensors that have reliable back-up power sources in order to ensure continued monitoring for all your remote site.

Many humidity monitoring devices are limited in function. Advanced devices are capable of integrating multiple monitoring technologies into a single unit. For example, depending on your business, it may be more efficient and cost-effective to look for a technology that integrates temperature sensors into your humidity monitoring system.

However, depending on your RTU, it becomes easy to incorporate multiple alarm systems for things such as doors, battery voltage, AC power, climate, smoke, floor water, fuel tanks, and more.

No matter what product you choose, integrating monitoring technologies is an effective way to maximize your network protection.

With increasing global temperatures and unexpected weather fluctuations, humidity monitoring is becoming increasingly relevant.

If you operate a business that uses electronic devices, humidity could pose a significant risk to your network's safety. By ensuring that you are always informed on the condition of your infrastructure, you can feel confident with your system's security and begin focusing on other challenges of growing your business.

We have more than 30 years of experience working with remote monitoring, that's simply all we do. As experts in network monitoring, we've dealt with many different situations and we've helped multiple different companies achieve their humidity monitoring goals. And we can help you too.

So don't leave your vital gear unprotected any longer. Contact us today and let's discuss a perfect-fit monitoring solution for your scenario.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.