Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayTemperature monitoring is only one fraction of environmental monitoring at your remote equipment sites and it's a critical part of keeping your network online.

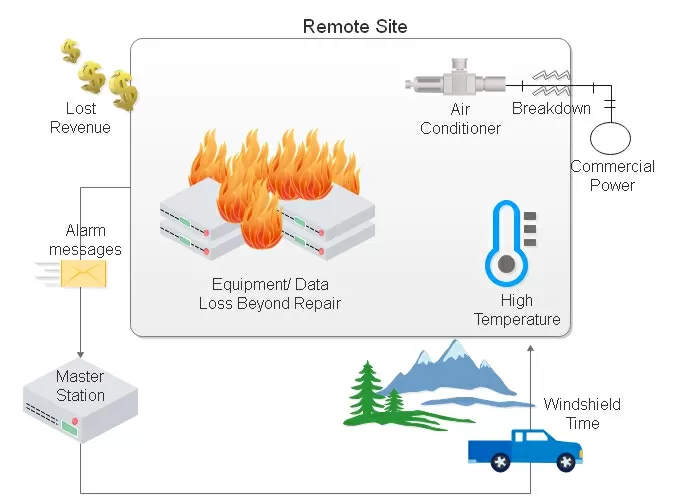

Your sites must have some form of temperature control to ensure an optimum operating environment for your equipment. If your equipment gets too hot or too col, it's likely to malfunction or even break, resulting in expensive repairs, and network downtime.

As an experienced monitoring solutions provider, we want you to know that you shouldn't have to wait for equipment to overheat or to get too cold to know that you have a problem. A proactive temperature monitoring device can provide you with useful alerts, but you need to know what to look for.

Let's take a look at the main best practices when choosing a temperature monitoring system, as well as main key features you should keep in mind.

Temperature monitoring is one of the key environmental alarms to monitor in every unmanned remote site. From both extremes of the temperature range, it's very important to monitor what conditions your revenue-generating equipment are operating under.

High temperatures are generally regarded as a bigger threat, because all computer equipment naturally generates large quantities of heat. If this heat is not reduced through venting and HVAC systems, your equipment can be damaged or, at minimum, suffer a thermal shutdown that will cause an interruption in service.

Cold temperatures are also a concern, especially at high elevations in the northern latitudes. In this case, a heater takes on the temperature controlling role normally perform by an HVAC system.

So, at both temperature spheres, a failure of your climate control system can lead to unacceptable network downtime. That's what makes temperature monitoring so important at all of your remote sites.

The answer to this question is simple. In its most basic form, all you need is a device that monitors the temperature and alerts you once the temperature reaches a certain point and becomes a problem.

While effective, this isn't the best solution. A technology that allows you to remotely monitor the precise temperature of your remote facilities online or with your smartphone is a better option.

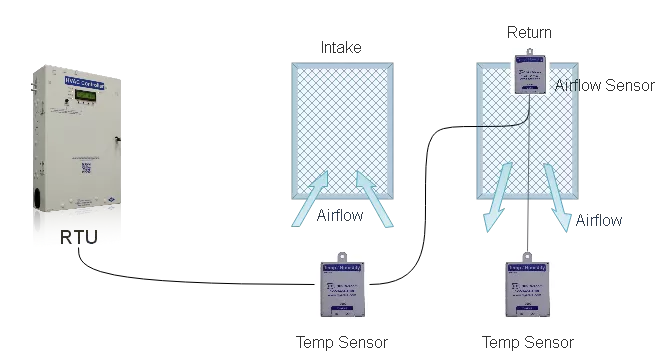

Remote telemetry units (RTUs) are capable of monitoring multiple temperature sensors, or analogs of other types. Some RTUs have built-in temperature sensors or a connection for an external temperature probe, which can be used to monitor ambient temperature or the temperature inside your sensitive equipment. With multiple analog inputs, you can either connect multiple temperature sensors and measure the temperature around the room or monitor for other conditions at your site - humidity, wind speed, fuel levels in your generators, and so on.

If you have a number of sites and are monitoring temperature at multiple locations, you'll also need a master station to poll and consolidate monitoring of your temperature sensors and other alarms.

While alerts from an RTU is more helpful than not receiving notification for high temperature at your site at all, having to remember which of your sites the alert came from, the location of the site, set point for your air conditioning, and other factors that will contribute to you better understanding and responding to the alarm situation, will take too long when you have a real emergency. It leaves too much room for errors.

Your master station, polling your sites and sending alerts, can give you access to more specific information about your sites and offer a single point of contact, making things easier on you and your team.

Not all temperature monitoring devices are created equal. You need to be careful when selecting a device, or you'll end up with a system that's destined for failure. Too many temperature monitoring systems fail to see the big picture and leave out critical features you can't live without - leading to more problems for you and your team.

So, to have an efficient temperature alarm monitoring it's crucial to keep the following key features in mind.

An important best practice is to monitor more than just temperature. For that it's important to make sure your monitoring system is capable of keeping an eye on all your remote site environmental factors.

Besides temperature, the following points are the most common environmental threats to network equipment:

Humidity

Excess humidity can cause the internal components of your equipment to rust and degrade - with the potential for short-circuiting. When the humidity is too low it can cause serious damage as well. When humidity is too low your IT equipment is susceptible to static electricity - which can short your equipment. That's why it's critical to keep the humidity at a moderate level.

You should have an environmental monitoring system that can notify you when the humidity is too low or too high, so you don't leave your equipment vulnerable to severe damage.

Water damage

Leaking water, just like high humidity, can cause major damage to your revenue-generating equipment. So, if water is present around your important gear, you need to know.

Allowing water to flood your equipment is easily prevented - as long as you're warned about its presence in time. Having the right monitoring technology will alert you of the presence of water so you can prevent serious damage.

Air flow

With more powerful processors being packed into smaller units, your equipment generates more heat than ever before. So, walking into your facility can be like walking into a furnace. One of the toughest challenges network operators face is cooling all of this equipment.

One of the most efficient ways to cool your gear is to design a system that optimally circulates the air flow around your equipment. Small disruptions to the flow of air could have severe consequences on the temperature of your equipment. That's why it's crucial to have air flow sensors in place - so you'll be the first to know if something is disrupting air flow to your equipment.

As you can see, using a monitoring system to monitor environmental variables can mean the difference between a giant headache and network uptime.

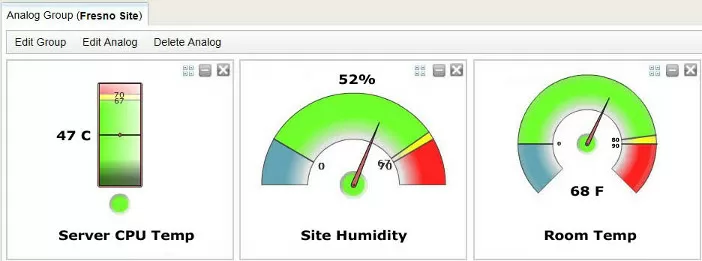

It's not enough to simply monitor temperature, a good practice is to have your monitoring device alert you when you actually have a problem, and you want to know the severity and nature of that problem - not simply that the temperature is too high or too low. It's critical to know how high or low and at least some indication as to why.

In order to achieve such level of visibility, it's important to choose analog sensors instead of discrete sensors. While discrete alarms are the most common type of network monitoring alarm, there are some applications best suited for analog alarms.

Discrete sensors collect digital information from equipment. By establishing a high/low threshold, you can receive an alert whenever the sensor detects that the alarm point crosses this threshold. Usually, discrete sensors are used for monitoring doors, tower lights, communication equipment, etc.

On the other hand, analog sensors collect live values from environmental conditions. This information is then reported to you as a real value, instead of just an "on" or "off" data. Due to this ability to present more accurate and precise information, analog sensors are commonly used to monitor things like temperature, battery voltage, power current, etc.

A common example of an analog application is the measurement of temperature. If you have analog alarm values to measure, you need to identify the thresholds at which your monitoring system will take charge.

For instance, image you're using a temperature alarm to measure the temperature of a remote site. Building temperatures range from 10 to 120 degrees Fahrenheit. Under normal circumstances, the building's heating and cooling system will keep the temperature within an acceptable range. To take advantage of multiple analog values, you might set up 4 different threshold values like below:

When the temperature is below 30 degrees, notify a technician and the Network Operations Center (NOC). A value this low might indicate that the heater is not working at all.

When the temperature is below 50 degrees, notify the NOC. This may indicate that the heater is not functioning properly.

When the temperature is above 80 degrees, notify the NOC. This may indicate that the air conditioning unit is not functioning properly.

When the temperature is above 100 degrees, notify a technician and the NOC, as well as open a vent (via derived controls). This may indicate that the air conditioning unit is not working at all.

With four thresholds you can establish separate major and minor alarms for both high and low temperatures. This gives you both an advanced warning if temperatures are starting to leave the ideal range (for example, the air conditioner is not working right and the temperature has risen to 80 degrees) and a final notification when temperatures have reached the danger point (for instance, the air conditioner is not working at all, and the temperature is 100 degrees).

Knowing both the inside and outside temperatures gives you the total picture. Imagine if the outside temperature is 150 degrees and your AC stopped working. With this knowledge you know you should dispatch a tech as soon as possible since the temperature is sure to rise fast.

So, to get effective visibility of remote site temperature, look for an RTU with four-threshold analog inputs for live monitoring of actual temperature levels.

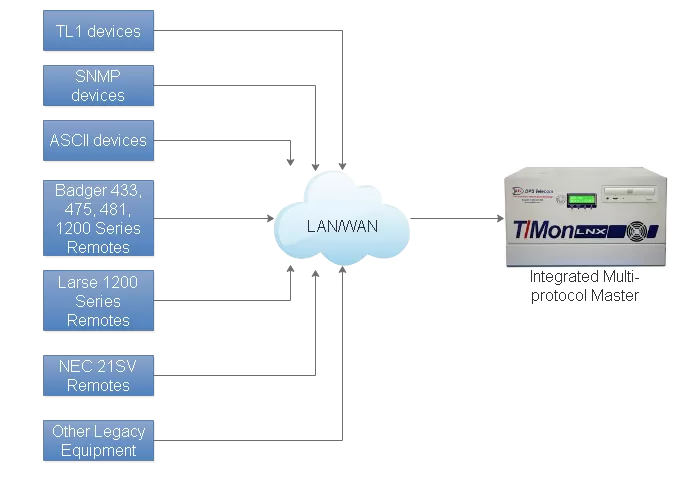

Temperature and other remote site environmental alarms can't be access and viewed separately from your whole network.

How many different devices do you monitor?

Most network managers are responsible for a wide range of equipment, such as switches, routers, microwave radios, and a variety of RTUs. Some output contact closures, others ASCII text alarms. You might work with SNMP or a proprietary protocol supported by only one manufacturer.

How many different remote alarm monitoring systems are you running to track all your alarms? How many different screens do you have to watch? How many consoles are cluttering up your NOC? How many alarm databases do you have to maintain?

Wouldn't you like to have one remote alarm monitoring system to manage your entire network?

For that, make sure your alarm master is a multiprotocol, multi-function remote alarm monitoring system designed as a single-platform solution for monitoring and mediating alarms at remote sites into a single, centralized location - regardless of manufacturer or protocol.

With an integrated remote alarm monitoring system, if there's a problem you'll know it in a timely manner. Here are some other benefits of network integration:

Track every alarm from every site on the same screen.

Every alarm notification is in the same format, so you can define and enforce standard alarm handling procedures. Your staff will immediately know what to do in case of an alarm.

You can alert your on-call techs for any alarm from any site. You don't have to worry that serious problems are piling up behind your back.

Integrate existing system without forklift swapouts. A multiprotocol remote alarm monitoring system can support your existing equipment, so you don't have to replace it.

The bottom line is that if you can't monitor your whole network on one screen, you'll miss a critical alarm - and a problem that could have been easily corrected will cause a service outage.

Temperature alarm monitoring is just the start of what you should be looking for in a remote telemetry unit and in a master station. Here's a handy checklist of all the essential features you should keep in mind.

Nuisance Alarm Filtering

It's very common for NOC staff to stop taking alarms seriously when they're constantly bombarded with status alerts, oscillating conditions, and unimportant alarms. Make sure your remote monitoring device can filter these out.

To prevent nuisance alerts, you can also set qualification timers as well. Qualification timers tell your RTU to set an alarm only when a condition has been present for a certain period of time.

So, for example, if you set a minor-over alarm to just above the set-point for your air conditioning system, you could likely receive an alarm before the air conditioning has taken affect, which would be relatively meaningless. However, if you set a qualification timer on that threshold for 5 minutes, then if you receive an alarm on that minor threshold, you'll know that either your air conditioning has not come on or it's not effectively cooling your site - which is much more useful information.

Root Cause Analysis

Finding the underlying cause between alarm cascades can take hours of patient detective work. A best practice is to look for a remote monitoring system that can automatically correlate repeated combination of alarms.

History and Trend Analysis

Identify the problem areas and eliminate recurring problems with a remote monitoring system that keeps a complete alarm history that you can export for trend analysis.

Custom Combination Alarms

A low battery isn't a serious problem, and neither is a failed generator, but you might agree that it's pretty serious when both situations happen at the same time. So, look for an RTU that is able to watch many different alarm inputs and spot critical alarm combinations.

Alarm Sorting

A large, complex network can create a cascade of alarms. Some are insignificant, but other of course are very serious. Look for RTUs that are able to automatically sort and prioritize this flood of information for you.

Multiprotocol Support for Your Current Devices

Make sure that your temperature monitoring device collects alarms from all your existing devices, including your older legacy gear. You can get rid of all your specialized consoles and monitor your network from one screen.

Back-up Dial-up Reporting

Don't rely only on your primary network to bring back alarms. If anything goes wrong with your transport, you'll lose your telemetry data just when you need it the most. Make sure your remote monitoring device supports dial-up alternate path reporting.

SNMP Support and Ping Alarms

If you're responsible for both telecom and IP equipment, consolidating all your monitoring on one screen will make your job a lot easier. For that you can integrate all your different equipment by mediating all your alarms to SNMP - from every type of equipment and every protocol you use, without losing any essential information in the process.

Also, an RTU that does support ping alarm will ping devices on your network at regular intervals. If a device fails to respond, the RTU will send an alarm as an SNMP trap, providing immediate notification that the device has failed or gone offline.

Control Relays

High-temperature alarms and other remote site problems, such as power outages, can be quickly solved through the remote operation of on-site equipment like air conditioning and generators. Remote operation of devices at remote sites is the best way to eliminate unnecessary truck rolls and windshield time.

Detailed Alarm Notifications

Summary major/minor alarms don't give you enough information to make dispatch decisions. Look for a remote monitoring device that includes detailed diagnostic information in each alarm.

Alarm Correction Instructions

Detailed instructions provided by alarm notifications ensure that system operators, without extra training, will know precisely what to do and who to call when an alarm happens.

Cell phone and Email Notifications

Cell phone and email notifications let your techs respond to alarms while they're still in the field, speeding repairs and reducing windshield time. So, look for a remote monitoring system with detailed alarm notifications support via text message and email.

Web Interface

Virtually everybody knows how to use a web browser. A web interface makes sure all your field techs can access your alarm system, from any computer from any location.

Once you received an alert, or simply to satisfy your own curiosity, you can access your monitoring devices by web to check temperature values in real time. Also, if you have a device that has at least a couple of control relays, and if your relays are wired to your site's HVAC systems, you can operate HVAC equipment directly from the web, solving your temperature alarm without having to make a trip out to a site.

In a nutshell, the idea behind deploying a remote temperature monitoring device is not to simply receive an alert when the temperature at your site reaches a critical level, but to be able to pinpoint the problem and fix it - so you can save your expensive equipment from damage and keep your network operational.

Now, that you know the main best practices when choosing your temperature monitoring system, it's time to know how you can get started protecting your equipment.

If you think that a truly effective system is probably way too complicated to setup and manage. Don't worry, though, this couldn't be further from the truth.

Protecting your network doesn't have to be a hassle - and it doesn't have to break your budget either. The first and most important step is making sure you have the right information to make the right choice.

To help you get started picking the right environment monitoring system, we've put together the Network Alarm Monitoring Fundamentals white paper. This free paper will give you solid instructions to alarm monitoring essentials and put you on the right path to making the right choices.

Download your copy and make sure you're getting a perfect-fit monitoring system.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.