Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIn this article, you will learn the meaning of RTU and how remote monitoring can be used to protect your network.

In Telecom and IT industries, a Remote Telemetry Unit or Remote Terminal Unit (RTU) is a microprocessor-based remote device that monitors and reports events occurring at a remote location.

Remote location means somewhere away from you or your central office. You might have multiple towers spread around the area you cover, not just at your office. To monitor one of the towers, you would have to be able to access your RTU "remotely."

Telemetry means the collection and processing of data, to ultimately transmit data from a remote source to you. Incorporating wireless remote telemetry adds flexibility and reduces the cost of running physical cables to each site.

This allows you, the network operator or telemetry technician, to manage the network more effectively, keeping service flowing to your customers and protecting your revenue stream.

Different from PLCs that require the knowledge of ladder logic, RTUs can be programmed through a simple web browser interface.

Some RTUs are also capable of remote controlling system devices using control relay contacts or protocol-based commands. Without this ability, an RTU only collects data and reports remote events to you. While this is valuable, you still must physically travel to the monitored location if a change must be made.

An RTU that includes remote control capability reduces costly truck rolls to a simple mouse click. Some are even capable of a fully automated response, especially when combined with advanced wireless remote telemetry solutions.

RTUs are important components of SCADA systems. Supervisory Control and Data Acquisition (SCADA) systems are used to monitor and control equipment and processes from remote sources. The SCADA architecture begins with RTUs since these devices are responsible for collecting information and sending it to you or your master station. Wireless remote telemetry ensures SCADA systems operate efficiently, even in geographically challenging areas.

An RTU will have multiple inputs and outputs. Inputs may monitor the power supply (main power line or backup battery modules) of the RTU itself or maybe even vital signs in certain health systems. An output may be a control relay to start a generator.

When looking for an RTU, ensure your vendor can give you exactly what you need. If you need wireless remote telemetry for long-range communication, your vendor should have no problem finding a solution for you. At DPS, we build customized, cost-effective telemetry systems to meet your needs.

RTUs are used in all sorts of businesses, from telecom to utilities to public safety and more. But let's delve deeper into the specifics of where RTUs truly shine.

RTUs play a crucial role in various industries, including:

Petrochemical Refineries: Ensuring smooth operation and safety in oil processing.

Nuclear Power Plants: Monitoring critical systems in high-stakes environments.

Agriculture: Enhancing productivity through precise control of irrigation and other processes.

Quality Control: Providing data for maintaining high standards across manufacturing.

Chemical Plants: Managing complex chemical processes with accuracy.

Sewage and Water Treatment Plants: Overseeing treatment processes to ensure environmental compliance.

Food Processing: Maintaining safety and efficiency in production lines.

Automobile and Pharmaceutical Manufacturing: Supporting automation and quality in production.

These devices are particularly valuable in remote and harsh environments. They excel where high temperatures, chemical exposure, or strong vibrations might cause other controllers to falter. RTUs are built to endure dust, high pressure, and other challenging conditions, making them indispensable for operations spread across wide areas.

By integrating RTUs into these diverse settings, businesses can achieve reliable monitoring and control, ensuring systems run smoothly and efficiently.

RTUs plays an important role in industrial and automation systems, incorporating essential components that enable smooth operation and reliable communication. The main components of an RTU include:

Each of these components is essential for the RTU to operate effectively within a larger automated system. Together, they allow for accurate monitoring and control across a range of industrial applications.

RTU units collect information from their local environments in several ways.

First, the gear that forms the backbone of your network will generally report problems as they occur. These reports take the form of discrete contact closure alarms or detailed protocol messages.

Second, your RTU may have onboard and external sensors that measure levels like temperature and humidity. Also, important technical values like battery and tank levels and power voltages may be monitored.

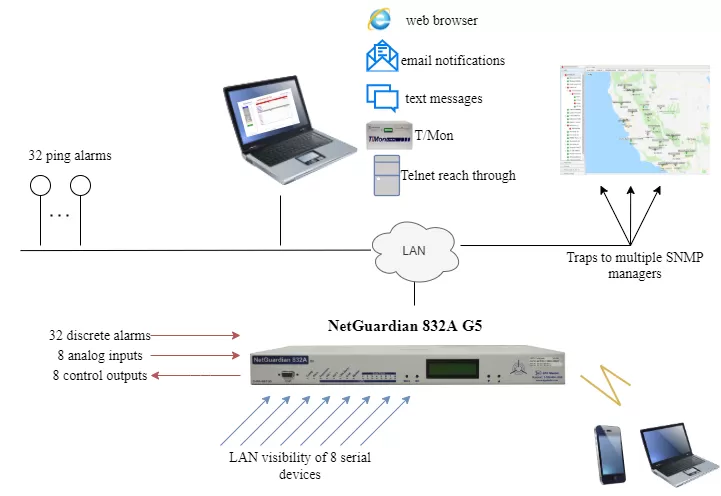

Once your RTU has collected important information, it needs a way to tell you about it. First, you have to choose one or more communication channels for the transmission of data. In many cases, you'll simply use LAN/Ethernet. For more remote sites (or those with legacy tech), you might use another method like a dial-up modem, wireless GSM/CDMA, or dedicated RS232/RS485 serial.

Once the channel is set, your RTU will use a protocol to send status information. One of the most common is SNMP ("Simple Network Management Protocol")

This is common on RTUs designed for either Telecom or IT environments. Directly monitored RTUs can use an onboard web interface that you can access from any web browser on the network. SCADA RTUs will tend to use DNP3 or Modbus to communicate.

Many older RTUs use protocols specific to the vendor that are only compatible with master stations from that same vendor. Another option would be a master station that supports multiple protocols like T/Mon.

With data logged from your RTU and sent as discussed above, how will you receive information so you can take action? In larger RTU deployments, you might have dozens or hundreds of units in the field. After ten or more units, we highly recommend investing in a master station. In its simplest form, a master station collects data from all RTUs and displays them to you in a single interface.

If you have just a few RTUs, you can monitor each unit using its web interface that displays events the RTU collected. More advanced RTUs and master stations can also send you a text message or phone calls to alert you to serious problems.

DPS Telecom even has a few clients who run sandwich shops (monitor temperature of deli meats), car washes (detect gear status and times when pipes might freeze and burst), and pig farms (pigs are very sensitive to changing temperatures and humidity).

In summation, an RTU is a device that provides supervisory control and data acquisition over remote sites. They're used in all sorts of businesses, from telecom to utilities to public safety and more.

While researching RTUs you probably have stumbled across mentions of PLCs or Personal Logic Computers. A PLC is an industrial digital computer designed for automating processes, including control of machinery on factory assembly lines, amusement rides, and lighting systems. It operates by receiving input signals from sensors, processing the information based on its programmed logic, and outputting control signals to actuators. PLCs are highly customizable, modular, and capable of handling complex tasks through extensive programming. Based on that description and what you have already learned it's obvious why these two different solutions are often compared but there are a handful of distinctions to keep in mind.

When comparing RTUs and PLCs, it's essential to understand their roles and functionalities within industrial settings. PLCs (Programmable Logic Controllers) are designed for local use, primarily in automated manufacturing. They excel at controlling devices like pumps, motors, and valves through high-speed, wired connections. This local operation often involves complex programming languages such as Ladder Logic or Structured Text, which necessitate specialized skills.

RTUs (Remote Terminal Units), however, are built for monitoring remote locations over large areas. They rely on wireless connections to communicate with the devices they oversee, making them ideal for applications where local infrastructure is limited. Unlike PLCs, RTUs can often be programmed through a straightforward web interface, eliminating the need for specialized software.

Environmental Adaptability: RTUs are engineered to endure harsh environments, including extreme temperatures, which makes them more rugged compared to PLCs that are suited for milder conditions.

Complexity and Components: An RTU functions like a self-contained computer, complete with a processor, memory, and storage. Some models even include backup power sources, such as batteries or solar panels, ensuring continuous operation without relying on primary power. This feature is particularly beneficial for applications demanding high reliability.

System Integration: RTUs can interface seamlessly with both DCS (Distributed Control Systems) and SCADA (Supervisory Control and Data Acquisition) systems, as well as other advanced control systems. While PLCs are primarily paired with SCADA systems, they often include a built-in display, allowing operators to interact directly with equipment status and alarms.

Cost Considerations: Due to their robustness and wide-area applicability, RTUs tend to be more expensive than PLCs. PLCs, being simpler and used for more straightforward processes, offer a cheaper solution for localized automation needs.

In conclusion, the choice between RTUs and PLCs should be guided by the specific requirements of the application, the environment, and the desired level of complexity and control.

RTUs: the building blocks of monitoring | Remote Telemetry Units FAQ

View Our Complete List of RTUs

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.